What Affects PCB Assembly Cost?

Date:2023-06-13 14:24:03

PCB assembly cost is one of the important factors affecting the cost of electronic products. When designing and manufacturing a PCB, many factors need to be considered to ensure that PCB assembly costs are minimized. The following are factors that affect the cost of PCB assembly:

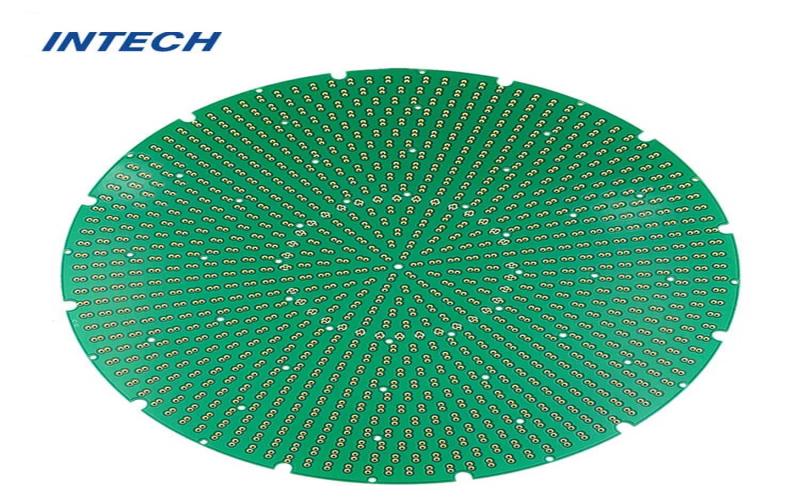

1. PCB size and complexity: PCB size and complexity are one of the main factors affecting PCB assembly cost. Larger and more complex PCBs require more material and longer manufacturing times, which increases assembly costs.

2. Number and type of components: PCB assembly cost also depends on the number and type of components. Using more components increases assembly costs, while using fewer components decreases assembly costs. In addition, the use of more expensive components also increases assembly costs.

3. Surface Mount Technology: Surface Mount Technology (SMT) is a commonly used PCB assembly technology, which can greatly reduce assembly costs. SMT technology can automate assembly, reduce manual operations, and improve production efficiency. However, SMT technology requires higher equipment and material costs, which also affects assembly costs.

4. Soldering technology: Soldering technology is one of the key steps in PCB assembly. Using manual soldering techniques will increase assembly costs, while using automated soldering techniques can reduce assembly costs. In addition, the use of high-quality welding materials and equipment can also increase the cost of assembly.

5. Production volume: Production volume is another important factor affecting PCB assembly cost. High-volume production can reduce assembly costs because it reduces manual handling and material waste. Conversely, low-volume production increases assembly costs because it requires more manual operations and higher material costs.

6. Design and Layout: PCB design and layout also affect assembly cost. Poor design and layout can result in components that are too close together or too far apart, which increases assembly costs. Therefore, good design and layout are required to ensure proper distance between components.

7. Quality Control: Quality control is one of the key factors to ensure PCB assembly costs are minimized. Quality control reduces assembly errors and material waste, thereby reducing assembly costs. Therefore, strict quality control measures need to be implemented to ensure the quality and reliability of PCB assembly.

In short, there are many factors that affect the cost of PCB assembly, which need to be considered comprehensively. When designing and manufacturing a PCB, attention needs to be paid to these factors to ensure that PCB assembly costs are minimized.