What is flexible PCB?

Date:2023-07-05 17:08:34

Introduction: The Advantages and Applications of Flexible PCBs

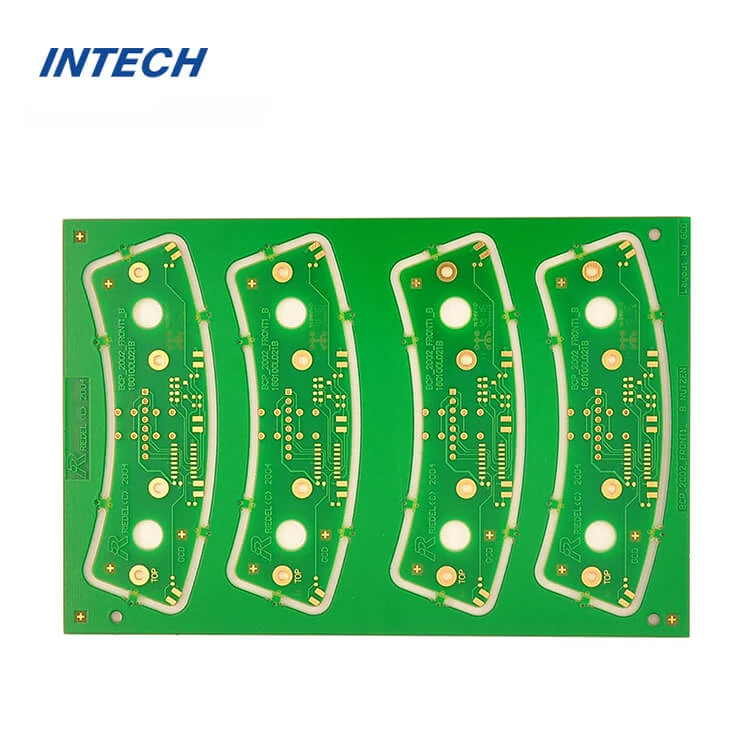

Flexible PCB, or flexible printed circuit board, is a highly versatile and adaptable circuit board that is revolutionizing the field of electronics. Unlike traditional rigid PCBs, flexible PCBs are made using flexible and bendable materials, such as polyimide, enabling them to be shaped and molded according to specific design requirements. This article delves into the various aspects of flexible PCBs, including their structure, benefits, and applications.

Structure and Components of Flexible PCBs

Flexible PCBs consist of several layers that are interconnected using conductive pathways. The base layer is made of a flexible material, often polyimide, which provides the board with its flexibility. On top of the base layer, a thin layer of copper is applied, forming the conductive traces on the PCB. These traces are responsible for carrying electrical signals and connecting the different components on the board. Additionally, a solder mask and silk screen may be added to protect the circuitry and provide labeling.

Benefits of Flexible PCBs

Flexible PCBs offer numerous advantages over traditional rigid PCBs, making them a preferred choice for many modern electronic applications. Some notable benefits include:

1. Flexibility and Bendability: The ability to flex and bend makes flexible PCBs ideal for applications where space and weight are constraints, or where complex and non-linear designs are required.

2. Enhanced Reliability: Flexible PCBs are highly resistant to vibrations, shocks, and movements, ensuring enhanced reliability in applications that experience physical stress.

3. Space and Weight Savings: The compact and thin nature of flexible PCBs allows for optimized use of available space, making them ideal for miniaturized and lightweight electronic devices.

4. Increased Design Freedom: The flexibility of the PCB material allows designers to create unique and unconventional shapes, enabling innovative and creative product designs.

5. Improved Signal Integrity: The shorter traces, reduced interconnection points, and controlled impedance of flexible PCBs minimize signal loss and interference, resulting in improved signal integrity.

Applications of Flexible PCBs

Flexible PCBs find widespread applications across various industries, including:

1. Consumer Electronics: Flexible PCBs are used in smartphones, tablets, wearable devices, and other consumer electronics, enabling sleek and compact designs.

2. Automotive: They are employed in automotive systems, such as engine control units, dashboard electronics, and LED lighting, due to their ability to withstand vibrations and temperature fluctuations.

3. Medical Devices: Flexible PCBs are used in medical equipment, such as defibrillators, pacemakers, and diagnostic devices, where their flexibility and compact size are advantageous.

4. Aerospace and Defense: They are applied in aerospace and defense applications, including satellites, radar systems, and military-grade electronics, ensuring reliability in extreme conditions.

5. Industrial Automation: Flexible PCBs are used in automation systems, industrial control panels, and robotic devices, thanks to their compact form factor and resistance to harsh environments.

Conclusion

Flexible PCBs have revolutionized the world of electronics with their incredible flexibility, compactness, and design freedom. Their numerous benefits, including increased reliability, space savings, and improved signal integrity, have made them indispensable in various industries. As technology continues to advance, the demand for flexible PCBs is expected to grow, driving further innovation and development in this field.