How does the manufacturing process differ for aluminum PCB?

Date:2024-01-18 03:10:20

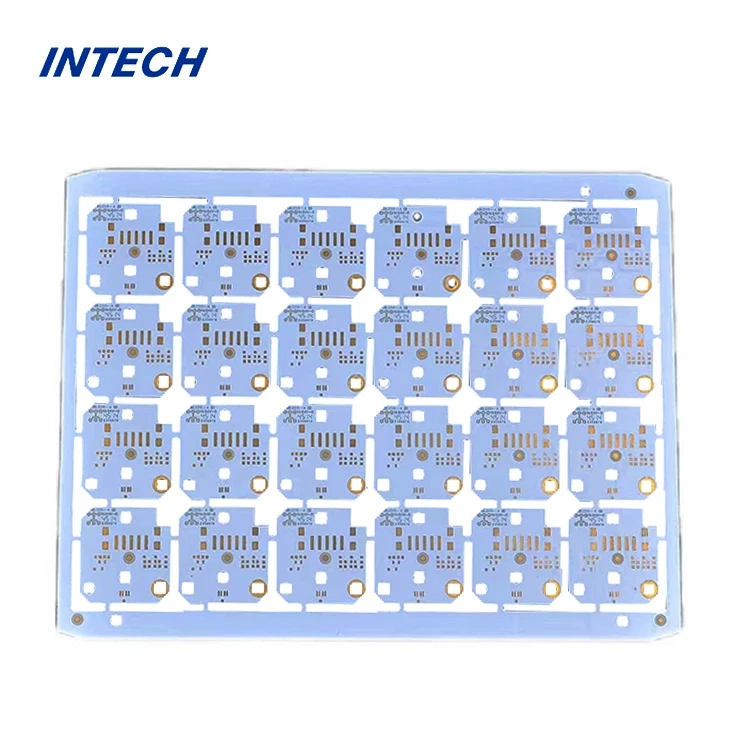

Aluminum PCBs (Printed Circuit Boards) have become increasingly popular in the electronics industry due to their unique properties, offering enhanced thermal performance and durability. In this article, we will delve into the manufacturing process of aluminum PCBs, exploring key aspects such as aluminum PCB board fabrication, the role of aluminum PCB manufacturers, and the importance of aluminum PCB prototyping.

1. Aluminum PCB Board Fabrication

a. Substrate Preparation

The manufacturing process begins with the preparation of the aluminum substrate. Thin layers of thermally conductive dielectric material are applied to the aluminum base, providing electrical insulation while facilitating efficient heat dissipation.

b. Circuit Layer Formation

A thin layer of copper is then laminated onto the dielectric material. This copper layer forms the conductive pathways that make up the circuitry of the PCB.

c. Photoresist Application

A layer of photoresist is applied to the copper surface. This photoresist layer is photosensitive and undergoes a chemical change when exposed to UV light, allowing for the transfer of the circuit pattern onto the copper.

d. Etching Process

The PCB undergoes an etching process where excess copper is removed, leaving behind the desired circuit traces. The remaining copper traces are now a functional part of the aluminum PCB.

e. Solder Mask Application

A solder mask layer is applied to protect the circuitry and define the areas where components will be soldered onto the PCB. This layer also adds an additional insulating barrier.

f. Surface Finish

The final step in aluminum PCB board fabrication involves applying a surface finish to protect the exposed copper and ensure solderability. Common surface finishes include HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold).

2. Role of Aluminum PCB Manufacturers

a. Material Selection

Experienced aluminum PCB manufacturers play a crucial role in selecting the right materials for the specific application. They consider factors such as thermal conductivity, dielectric properties, and mechanical strength to ensure optimal performance.

b. Advanced Manufacturing Equipment

Leading manufacturers utilize advanced equipment for precise fabrication. CNC machines, laser drills, and automated assembly lines contribute to the accuracy and efficiency of the manufacturing process.

c. Quality Control

Quality control is paramount in aluminum PCB manufacturing. Manufacturers implement rigorous testing procedures to identify and rectify any defects, ensuring that the final product meets industry standards.

3. Importance of Aluminum PCB Prototyping

a. Design Validation

Aluminum PCB prototyping allows for the validation of the design before mass production. This step helps identify and address any potential issues early in the process, saving time and resources.

b. Performance Testing

Prototyping enables thorough performance testing, especially concerning thermal management. Engineers can assess how well the aluminum PCB dissipates heat and make adjustments to enhance efficiency.

c. Customization Opportunities

Prototyping offers the flexibility to customize designs based on specific project requirements. Engineers can experiment with different layouts and configurations to achieve optimal performance.

Conclusion

In conclusion, the manufacturing process of aluminum PCBs involves several critical steps, from substrate preparation to surface finishing. The role of aluminum PCB manufacturers is vital in material selection, advanced fabrication, and quality control. Additionally, aluminum PCB prototyping serves as a valuable stage in design validation, performance testing, and customization, ensuring that the final product meets the high standards demanded by the electronics industry