What future trends are expected in PCB flex-rigid technology?

Date:2024-03-20 03:34:37

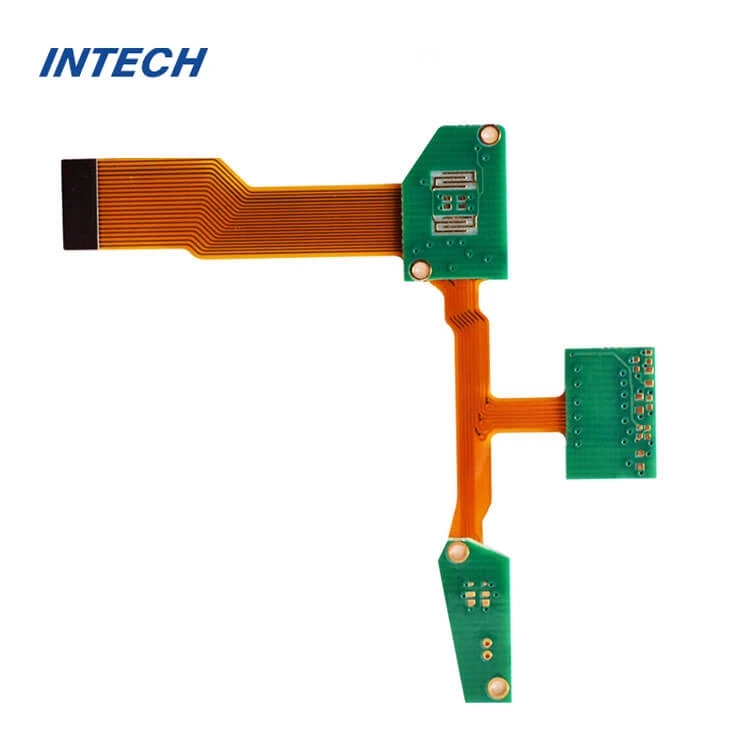

PCB flex-rigid technology has revolutionized the field of electronics, enabling the development of compact, lightweight, and highly functional devices. As technology continues to evolve, several emerging trends are shaping the future of PCB flex-rigid technology. In this article, we delve into these trends, exploring their potential impact on product design, manufacturing processes, and the broader electronics industry.

1. Miniaturization and Integration:

As consumer demand for smaller and more portable devices grows, miniaturization and integration will remain key trends in PCB flex-rigid technology. Manufacturers are exploring innovative ways to reduce the size and weight of PCB assemblies while integrating more features and functionality into compact form factors. Advanced design techniques, such as stacked and nested flex-rigid configurations, will enable the creation of increasingly dense and complex PCB layouts.

2. High-Speed and High-Frequency Applications:

With the proliferation of high-speed data transmission and wireless communication technologies, PCB flex-rigid designs optimized for high-frequency applications are becoming increasingly prevalent. Future trends in this space will focus on enhancing signal integrity, minimizing crosstalk, and reducing electromagnetic interference (EMI). New materials with improved dielectric properties and lower signal loss will enable the development of high-speed flex-rigid assemblies capable of meeting stringent performance requirements.

3. Flexible and Wearable Electronics:

The rise of flexible and wearable electronics represents a significant opportunity for PCB flex-rigid technology. Future trends in this domain will center on the development of flexible substrates, stretchable interconnects, and conformal electronics for wearable applications. Innovations in materials science and manufacturing processes will enable the creation of flexible PCBs that can bend, twist, and conform to irregular shapes, opening up new possibilities for wearable devices in healthcare, fitness, fashion, and beyond.

4. 3D Integration and Multi-Layer Structures:

3D integration techniques, such as through-silicon vias (TSVs) and stacked die assemblies, offer immense potential for enhancing PCB flex-rigid technology. Future trends in this area will focus on leveraging 3D integration to achieve higher levels of functionality and performance in compact form factors. Multi-layer flex-rigid structures will enable the integration of diverse components, including sensors, microcontrollers, and RF modules, in vertically stacked configurations, reducing footprint and improving system-level integration.

5. Advanced Materials and Manufacturing Processes:

Advancements in materials science and manufacturing processes will drive future innovation in PCB flex-rigid technology. New materials with enhanced mechanical properties, thermal conductivity, and reliability will enable the development of more robust and durable flex-rigid assemblies. Additionally, advances in additive manufacturing, such as 3D printing of flexible substrates and conductive inks, will democratize the prototyping and production of custom flex-rigid designs, accelerating the pace of innovation in the electronics industry.

6. Sustainability and Environmental Responsibility:

With increasing awareness of environmental issues and regulatory requirements, sustainability will emerge as a key trend in PCB flex-rigid technology. Future developments will focus on reducing the environmental impact of PCB manufacturing processes, optimizing material usage, and enhancing end-of-life recyclability. Eco-friendly materials, such as bio-based polymers and recyclable substrates, will gain traction, enabling the production of environmentally responsible flex-rigid assemblies that meet stringent sustainability standards.

Conclusion:

The future of PCB flex-rigid technology is characterized by innovation, versatility, and adaptability. As technology continues to evolve, manufacturers will continue to push the boundaries of what is possible with flex-rigid designs, unlocking new opportunities for product development and differentiation. By embracing emerging trends and investing in research and development, the electronics industry can harness the full potential of PCB flex-rigid technology to create the next generation of smart, connected devices.