PCB Circuit Board Heat Dissipation Tips

Date:2024-07-11 14:04:34

The heat generated by electronic equipment during operation causes the internal temperature of the equipment to rise rapidly. If the heat is not dissipated in time, the equipment will continue to heat up, which may cause the following effects:

Impact on the reliability of structures such as PCB and electronic components: PCB is in high temperature, thermal expansion and contraction, causing the pad to become brittle, the plate to deform, the copper sheet to expand, and other problems that seriously affect the reliability of PCB. Impact on integrated circuits: For transistor circuits, temperature rise will cause the concentration of minority carriers in the PN junction to increase sharply, resulting in an increase in the current amplification factor and burning the circuit. For MOS process circuits, similarly, temperature rise will cause the current to increase, forming positive feedback, causing the temperature to rise higher and higher until it burns.

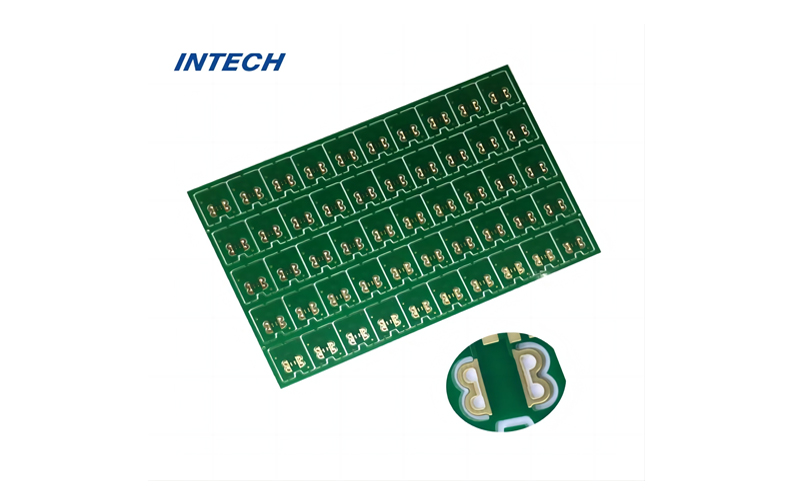

Classification of printed circuit boards

1. Single-sided boards

On the most basic PCB, the parts are concentrated on one side and the wires are concentrated on the other side (the same side as the wires when there are SMD components, and the plug-in devices are on the other side).

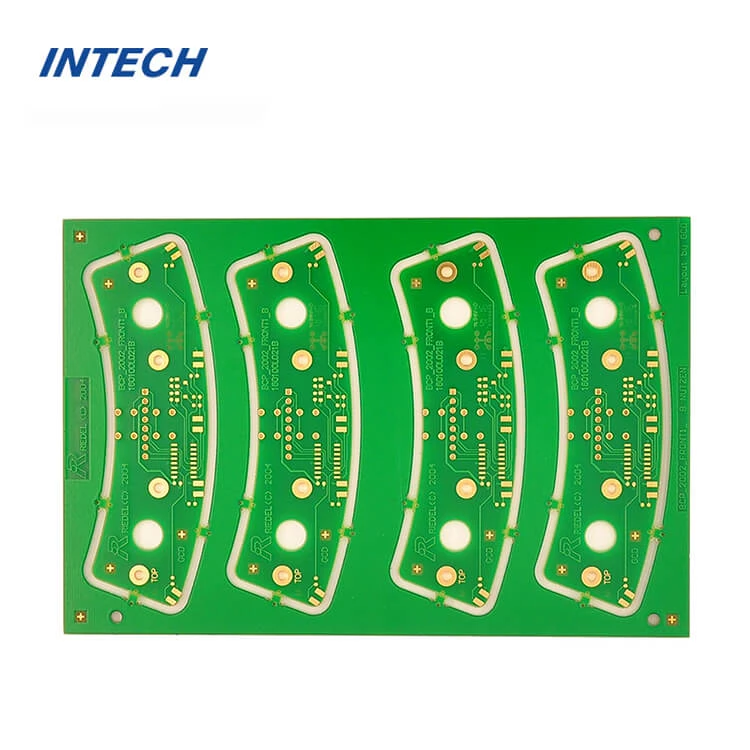

2. Double-sided boards

Double-sided boards (Double-sided boards) have wiring on both sides of this type of circuit board, but to use the wires on both sides, there must be an appropriate circuit connection between the two sides.

3. Multilayer Boards

In order to increase the area that can be wired, multilayer circuit boards use more single-sided or double-sided wiring boards.

Add heat sinks and heat conducting plates to high-heat devices. When a few devices on the PCB generate a lot of heat (less than 3), a heat sink or heat pipe can be added to the heat-generating device. When the temperature cannot be lowered, a heat sink with a fan can be used to enhance the heat dissipation effect. When there are a large number of heat-generating devices (more than 3), a large heat dissipation cover (board) can be used. It is a special heat sink customized according to the position and height of the heat-generating device on the PCB board, or a large flat heat sink with different component heights cut out. The heat dissipation cover is buckled on the component surface as a whole, and it contacts each component to dissipate heat. However, due to the poor height consistency of components during soldering, the heat dissipation effect is not good. Usually, a soft thermal phase change thermal pad is added to the component surface to improve the heat dissipation effect.

Heat dissipation through the PCB circuit board itself. The widely used PCB circuit board materials at present are copper-clad/epoxy glass cloth substrates or phenolic resin glass cloth substrates, and a small amount of paper-based copper-clad boards are also used. Although these substrates have excellent electrical and processing properties, they have poor heat dissipation. As a heat dissipation path for high-heat-generating components, it is almost impossible to expect the PCB resin to conduct heat, but to dissipate heat from the surface of the component to the surrounding air. However, as electronic products have entered the era of miniaturization, high-density installation, and high-heat assembly, it is not enough to rely solely on the surface of the component with a very small surface area to dissipate heat. At the same time, due to the large-scale use of surface-mounted components such as QFP and BGA, the heat generated by the components is transferred to the PCB board in large quantities. Therefore,