How Does Rigid PCB Improve Performance in Electronics?

Date:2024-10-24 11:02:17

Rigid printed circuit boards (PCBs) are a key component in modern electronics, offering durability, stability, and excellent performance. From consumer gadgets to industrial machinery, rigid PCBs provide a reliable platform for intricate circuits. But how exactly do they enhance the performance of electronic devices? In this article, we’ll explore the advantages of rigid PCBs and why they are widely used across various industries.

1. High Durability and Reliability

One of the primary reasons rigid PCBs improve performance in electronics is their structural integrity. Unlike flexible PCBs, rigid PCBs are made from solid materials, usually a fiberglass substrate, which provides long-lasting durability. This rigid structure ensures that the board retains its shape and withstands mechanical stress, vibrations, and impacts.

When it comes to high-performance electronics, especially in industries like automotive, aerospace, and medical devices, the reliability offered by rigid PCBs is crucial. These PCBs are built to function in demanding environments, ensuring that the electronic components remain securely connected, even under harsh conditions.

2. Enhanced Signal Integrity

Rigid PCBs are designed to improve signal integrity in complex circuits, which is essential for high-speed electronic devices. The stable and sturdy design of rigid PCBs minimizes electromagnetic interference (EMI) and radio frequency interference (RFI). These factors contribute to better performance, particularly in devices where data transmission is critical, such as communication systems and high-frequency applications.Rigid PCBs are often preferred by manufacturers for their ability to maintain high electrical performance across various layers. The precise construction and multilayered designs make them suitable for devices requiring multiple circuit paths while minimizing the risk of signal loss.

3. Customizability and Versatility

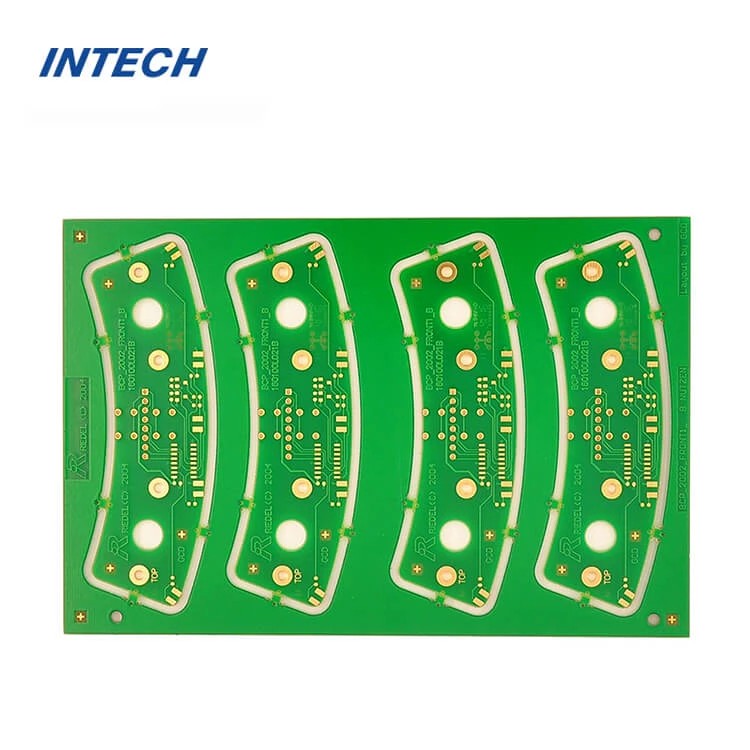

Rigid PCBs can be easily customized to meet the specific needs of different applications. Manufacturers can produce these boards in various sizes, thicknesses, and layers, depending on the complexity of the circuit design. This flexibility allows rigid PCBs to be used in a wide range of devices, from simple consumer electronics to sophisticated industrial machines.In addition, rigid PCB manufacturers can produce multilayer PCBs that allow for compact, efficient designs, essential for devices where space is limited, such as smartphones and wearable technology. The ability to stack multiple layers without compromising on performance is a major advantage for engineers and designers.

4. Heat Resistance

Electronics that generate a significant amount of heat, such as power electronics, benefit from the heat resistance of rigid PCBs. These boards are designed to dissipate heat efficiently, preventing damage to sensitive components. Rigid PCBs can be paired with heat sinks or thermal pads to further enhance heat management, which is particularly important in high-power applications.In environments where temperatures fluctuate drastically, rigid PCBs maintain their performance, ensuring that electronic systems remain stable and efficient over time.

5. Cost-Effective Manufacturing

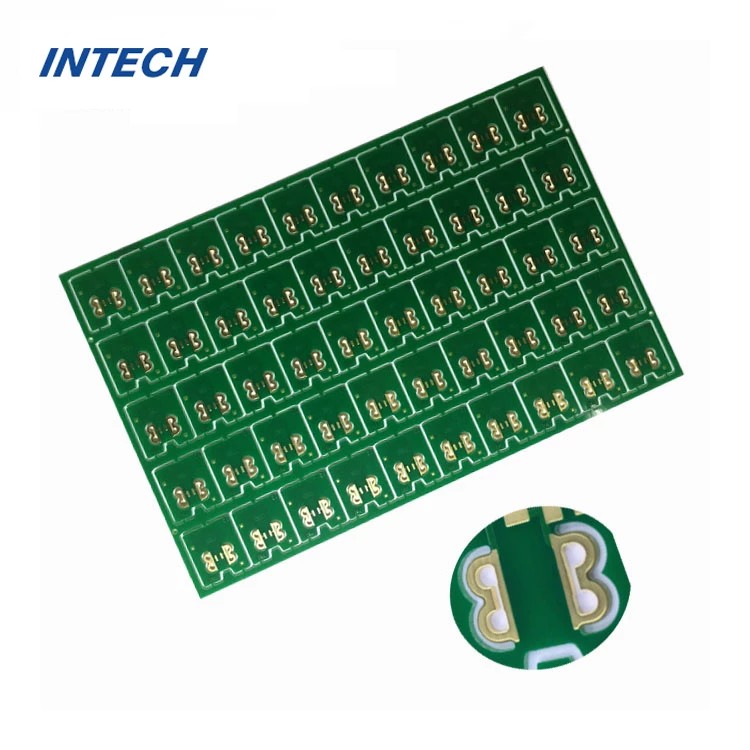

For high-volume production, rigid PCBs are often a cost-effective option. Many rigid PCB factories and suppliers offer competitive pricing for bulk orders, making it a practical choice for large-scale projects. The availability of a wide range of materials and components further reduces production costs, without compromising on the performance and reliability of the end product.

When sourced from reputable rigid PCB manufacturers, businesses can expect high-quality products that are not only affordable but also meet industry standards for performance and safety.

6. Long Lifespan and Low Maintenance

Rigid PCBs are known for their longevity. Once installed, these boards typically require minimal maintenance, which is beneficial for both manufacturers and end-users. The durability of the rigid materials ensures that the PCB will last longer compared to flexible alternatives, even in high-stress environments.This long lifespan means fewer replacements, reducing the overall cost of ownership and improving the efficiency of electronic devices in the long run.

Rigid PCBs play a pivotal role in enhancing the performance of electronic devices by offering durability, heat resistance, and improved signal integrity. Their versatility and customizability make them suitable for a variety of applications, from consumer electronics to industrial equipment. Partnering with a reliable rigid PCB manufacturer, factory, or supplier ensures that your electronic products benefit from the superior performance that rigid PCBs provide.