PCB Manufacturers Share: What Makes a Circuit Board More Heat-Resistant?

Date:2024-12-09 15:03:12

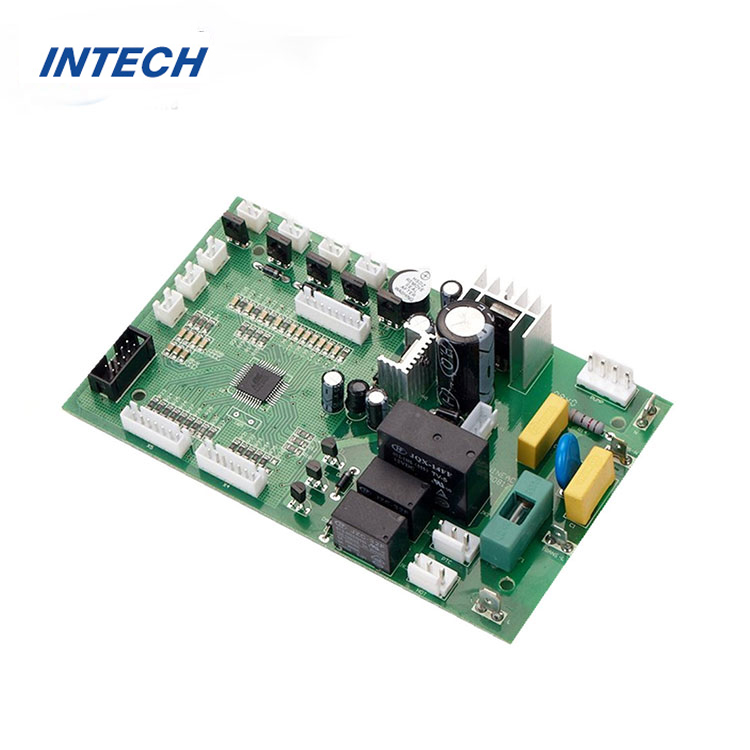

In the electronics industry, heat resistance is a critical factor in the performance and durability of circuit boards. From consumer gadgets to industrial machinery, circuit boards are subjected to varying levels of thermal stress during operation. Understanding what makes a printed circuit board (PCB) more heat-resistant can help manufacturers and designers create products that last longer and perform reliably. In this article, we’ll explore the key factors influencing PCB heat resistance, with insights from leading industrial PCB manufacturing experts and PCB board makers.

Why Is Heat Resistance Important in PCBs?

Circuit boards serve as the foundation for electronic components, which often generate heat during operation. Excessive heat can lead to issues such as:

- Component degradation or failure.

- Signal integrity problems.

- Deformation of the PCB material.

- Reduced overall product lifespan.

For industries relying on custom printed circuit boards, ensuring heat resistance is vital for maintaining product reliability, especially in applications such as automotive electronics, industrial controls, and aerospace systems.

Factors That Influence PCB Heat Resistance

1. Base Material Selection

The material used in PCB manufacturing plays a significant role in determining heat resistance. Common base materials include:

- FR-4 (Flame Retardant-4): Widely used for its balance of thermal performance and affordability. It can withstand temperatures up to 130°C in standard grades and higher in specialized grades.

- Polyimide: Known for its excellent heat resistance, polyimide can handle temperatures exceeding 250°C, making it ideal for high-performance applications.

- Ceramic-based PCBs: Often used in industrial PCB manufacturing, ceramic PCBs offer superior thermal conductivity and can endure extreme heat.

The choice of material depends on the application’s thermal requirements and budget constraints.

2. Copper Thickness

The thickness of the copper layer in a PCB directly affects its heat dissipation capacity. Thicker copper layers improve thermal conductivity, allowing the PCB to handle higher current loads without overheating. This is particularly important in applications involving power electronics or industrial systems.

3. Thermal Management Features

PCB board makers integrate various thermal management features to enhance heat resistance, including:

- Thermal Vias: These are holes plated with copper, allowing heat to transfer from one layer to another for improved dissipation.

- Heat Sinks: Adding heat sinks to a PCB can draw heat away from critical components.

- Thermal Pads: These are placed beneath components to conduct heat away efficiently.

4. Solder Mask and Surface Finish

The solder mask and surface finish of a PCB can also impact its heat resistance. High-temperature solder masks provide an extra layer of protection, while surface finishes like ENIG (Electroless Nickel Immersion Gold) offer durability under thermal stress.

5. Design Considerations

Proper PCB design is crucial for optimizing heat resistance. Custom printed circuit board designers often use the following techniques:

- Component Placement: Arranging heat-generating components strategically to minimize thermal hotspots.

- Trace Width and Spacing: Wider traces can handle more current and dissipate heat effectively.

- Multilayer Design: Distributing thermal loads across multiple layers enhances heat dissipation.

Applications Requiring Heat-Resistant PCBs

Certain industries place high demands on PCB thermal performance. For example:

- Industrial Electronics: PCBs in industrial machines often operate in high-temperature environments and must be durable enough to endure prolonged thermal exposure.

- Automotive Electronics: Circuit boards in vehicles face both high ambient temperatures and heat generated by electronic systems.

- Aerospace and Defense: Extreme temperature fluctuations in these applications require robust thermal management.

Industrial PCB manufacturing processes often focus on optimizing heat resistance to meet these demanding applications.

How to Choose a Heat-Resistant PCB Manufacturer

Selecting the right PCB board maker is essential to ensure that your circuit boards meet the necessary thermal performance standards. Look for manufacturers with expertise in:

- Custom printed circuit board solutions: Tailored designs to meet specific thermal requirements.

- Advanced materials: Access to high-performance substrates like polyimide and ceramic.

- Testing and quality assurance: Rigorous testing for thermal reliability.

Reputable manufacturers, like those specializing in industrial PCB manufacturing, can guide you through material selection, design optimization, and production to achieve the desired heat resistance.

Conclusion

Heat resistance is a vital characteristic of any PCB, particularly in demanding industrial and high-performance applications. Factors like material selection, copper thickness, thermal management features, and thoughtful design all contribute to the thermal reliability of a circuit board.By working with experienced PCB board makers and industrial PCB manufacturing experts, you can ensure that your custom printed circuit boards are built to withstand thermal stress and perform reliably in any application. Whether you’re designing for consumer electronics or industrial systems, prioritizing heat resistance is a key step in delivering durable and high-quality products.