Is It Better for the PCB to Be Green?

Date:2024-12-24 14:18:25

When it comes to printed circuit boards (PCBs), the color of the board is often a topic of curiosity. Among the various colors available, green seems to be the most common. But is it better for the PCB to be green? In this article, we’ll explore the factors behind PCB color choices and why green has become the industry standard, with a focus on its practical and aesthetic advantages. If you're looking for high-quality PCBs, Intech offers a variety of options to suit your needs.

1. The Role of Color in PCB Manufacturing

PCBs are essential components in electronic devices, connecting different parts of the circuit to ensure smooth and reliable functioning. The color of a PCB is influenced by the solder mask used during manufacturing, which helps protect the copper traces on the board. While the color of the solder mask doesn’t affect the performance of the PCB, it does serve several practical purposes.

2. Why Is Green the Most Popular Color for PCBs?

The widespread use of green PCBs can be attributed to several reasons:

Cost-Effectiveness: Green solder mask is the most common and economical choice for PCB manufacturing. It is readily available and relatively inexpensive compared to other colors.

Visibility: The green color offers excellent contrast with the copper traces, making it easier for engineers to spot issues during inspection and assembly.

Heat Dissipation: Although PCB color itself doesn’t directly affect heat dissipation, green solder masks are often paired with high-quality materials that optimize heat management. This is crucial for maintaining the performance and longevity of the board.

Manufacturing Standard: Over time, green has become the industry standard, ensuring consistency across products and making it easier for manufacturers to streamline production processes.

3. Can a PCB Be Other Colors?

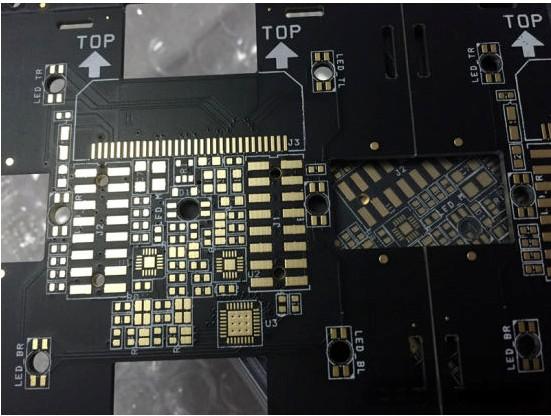

While green is the most common, PCBs can be manufactured in various colors, including red, blue, black, yellow, and even purple. These color choices are primarily driven by aesthetics or specific design requirements rather than performance. However, there are a few considerations:

Red and Blue PCBs: These are often chosen for specialized applications where visibility of the traces or a unique design is essential. For example, blue is popular for military and aerospace industries because it can enhance the visibility of components.

Black PCBs: Black PCBs have become increasingly popular for high-end consumer products due to their sleek, modern look. However, they tend to cost more than green PCBs because of the specialty materials involved.

Yellow and Other Colors: These colors are less commonly used, but can provide a distinctive appearance for specific products or branding purposes.

4. Does PCB Color Affect Performance?

No, the color of the PCB itself does not directly influence the performance of the electronic device. The electrical properties, such as signal integrity, power delivery, and heat management, are determined by the PCB's material and design, not by its color. However, certain factors such as the type of solder mask and the quality of manufacturing processes can impact the overall quality and durability of the PCB.

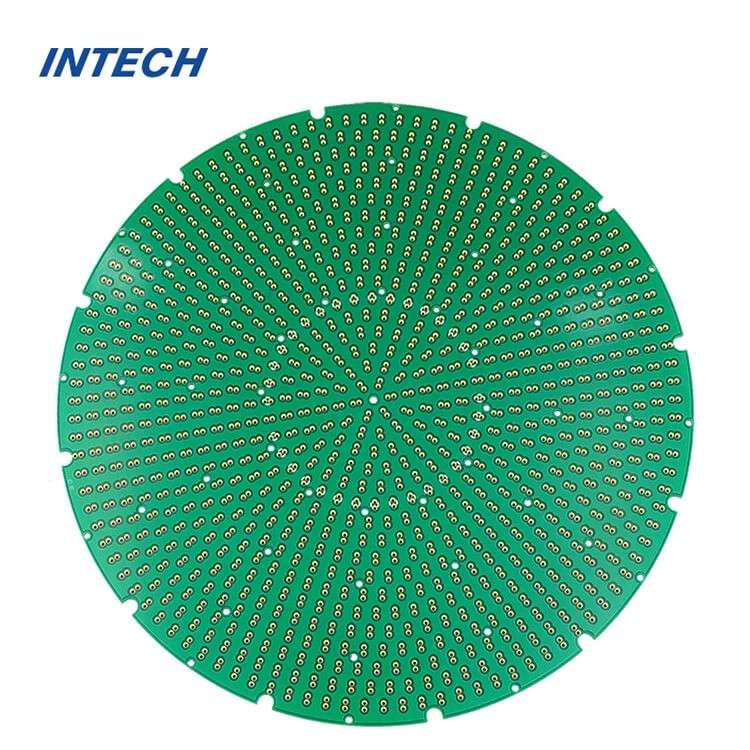

5. Intech’s Commitment to Quality PCBs

At Intech, we understand that the quality of your PCB is crucial to the success of your electronic devices. Whether you need green PCBs for standard applications or specialized colors for unique designs, we offer top-tier PCB manufacturing services that meet industry standards. Our focus is on ensuring that your products are reliable, cost-effective, and delivered on time.

While green is often seen as the standard PCB color due to its cost-effectiveness, visibility, and historical significance, the choice of color ultimately depends on your specific needs. For most applications, green is perfectly suitable, but if your project requires a different look or specific functionality, other colors are available. Whether you're designing consumer electronics or high-tech devices, Intech can provide the quality PCBs you need for optimal performance.

FAQ:

1. Why are PCBs usually green?

Green is the most popular PCB color because it’s cost-effective, easy to manufacture, and provides good contrast with the copper traces for inspection purposes.

2. Does the color of a PCB affect its performance?

No, the color of a PCB does not affect its electrical performance. The material and design of the PCB are what impact its functionality, not the solder mask color.

3. Are there other colors available for PCBs?

Yes, PCBs can be made in various colors, including red, blue, black, yellow, and more. The choice of color is typically based on aesthetics or specific requirements rather than performance.

4. How can I choose the right color for my PCB?

Consider factors such as aesthetics, branding, visibility of traces, and cost when choosing the PCB color. Green is generally the most economical and widely used option, but other colors may be better suited for special applications.

5. Can I get custom PCBs from Intech?

Yes, Intech offers a wide range of PCB solutions, including custom designs with different color options. We focus on quality and precision to meet your specific requirements.