Rigid Flex PCB Manufacturer: How to Choose the Best Supplier for Your Needs

Date:2025-03-14 16:49:57

As electronic devices become smaller, more complex, and require greater flexibility, rigid flex PCBs have become the preferred solution for high-performance applications. Whether you’re in aerospace, medical, or consumer electronics, choosing the right rigid flex PCB manufacturer is crucial to ensuring quality, durability, and efficiency in your products. In this article, we’ll explore the key factors to consider when selecting a rigid flex PCB supplier and how to ensure you get the best PCBs for your specific needs.

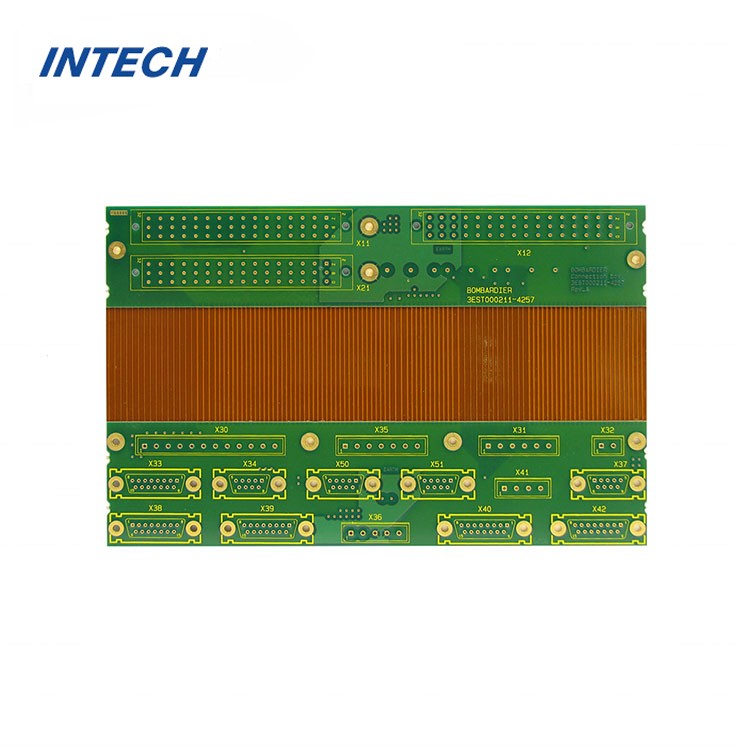

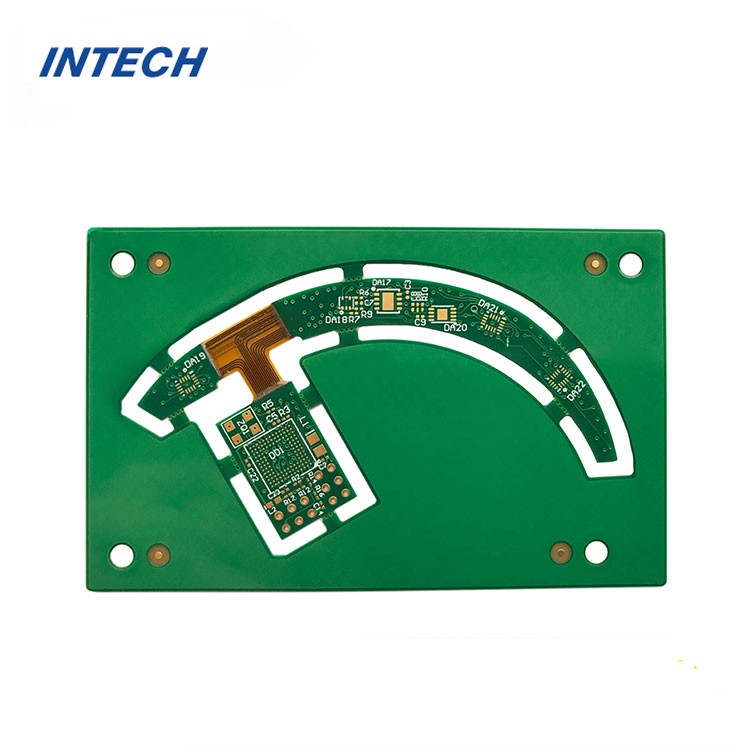

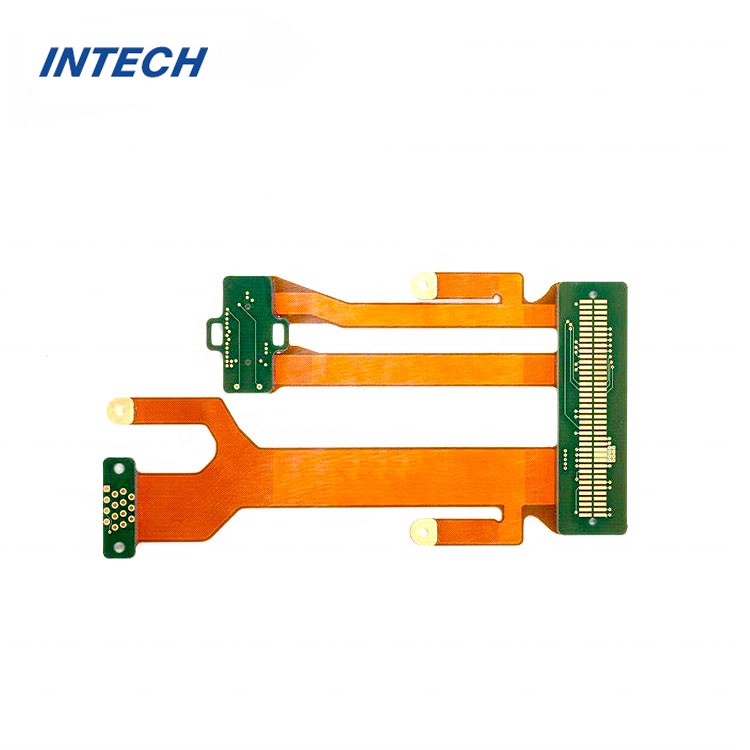

What Is a Rigid Flex PCB?

A rigid flex PCB combines the advantages of both rigid and flexible circuit boards into a single structure. These hybrid PCBs improve reliability by reducing the number of connectors and solder joints, which are common points of failure in traditional PCBs. They are widely used in industries where space constraints and durability are critical, such as:

- Aerospace and Defense – Lightweight and durable solutions for mission-critical applications.

- Medical Devices – Compact and highly reliable circuits for life-saving technology.

- Consumer Electronics – Foldable and wearable devices that require flexibility.

- Automotive and Industrial Equipment – High-performance PCBs for harsh environments.

Key Factors When Choosing a Rigid Flex PCB Manufacturer

Selecting the right rigid flex PCB manufacturer requires careful evaluation. Here are the most critical factors to consider:

1. Manufacturing Capabilities

Not all manufacturers can produce custom rigid flex PCBs that meet high industry standards. Look for suppliers with:

- Advanced fabrication technology – Ensure they have expertise in multi-layer, HDI, and fine-line PCB production.

- Precision and quality control – Verify ISO 9001, IPC-6013, and other industry certifications.

- Material expertise – The manufacturer should offer a variety of polyimide and FR4 materials for different applications.

2. Customization and Engineering Support

A reliable rigid flex PCB supplier should provide custom design support to meet your exact specifications. Look for:

- Prototyping services – Fast turnaround times for testing and development.

- DFM (Design for Manufacturing) guidance – Assistance in optimizing designs for cost and performance.

- Flexible production capabilities – The ability to scale from small batches to mass production.

3. Quality Assurance and Testing

To ensure high reliability, a rigid flex PCB manufacturer must conduct rigorous testing, including:

- Electrical testing (E-test) – Detects shorts, opens, and other defects.

- Thermal cycling and reliability testing – Ensures durability in extreme conditions.

- Micro-section analysis – Examines the internal structure of PCBs for quality assurance.

4. Industry Experience and Reputation

Choose a rigid flex PCB supplier with a proven track record. Look for:

- Customer reviews and testimonials – Check feedback from past clients.

- Case studies and reference projects – Verify their experience in your industry.

- Longevity in the market – Established manufacturers often offer better reliability.

5. Cost and Lead Time

While cost is important, it shouldn’t compromise quality. When evaluating a manufacturer:

- Compare quotes from multiple suppliers.

- Consider total cost, including prototyping, production, and shipping.

- Check their standard lead time and ability to handle urgent orders.

Top Benefits of Choosing the Right Rigid Flex PCB Manufacturer

By selecting a high-quality rigid flex PCB manufacturer, you gain several advantages:

✅ Enhanced Reliability – Fewer solder joints reduce failure rates.

✅ Space-Saving Design – Ideal for compact electronic devices.

✅ Improved Signal Integrity – Shorter interconnections minimize signal loss.

✅ Increased Durability – Withstands vibration, bending, and harsh environments.

Final Thoughts:

Choosing the right rigid flex PCB manufacturer is essential for ensuring the success of your electronics project. By considering factors such as manufacturing capabilities, quality assurance, and industry experience, you can find a rigid flex PCB supplier that meets your needs. Whether you need custom rigid flex PCBs for aerospace, medical, or consumer applications, investing in a trusted rigid flex circuit board manufacturer will provide long-term reliability and performance.