How do pcb assemblies get ordered?

Date:2023-12-25 16:07:35

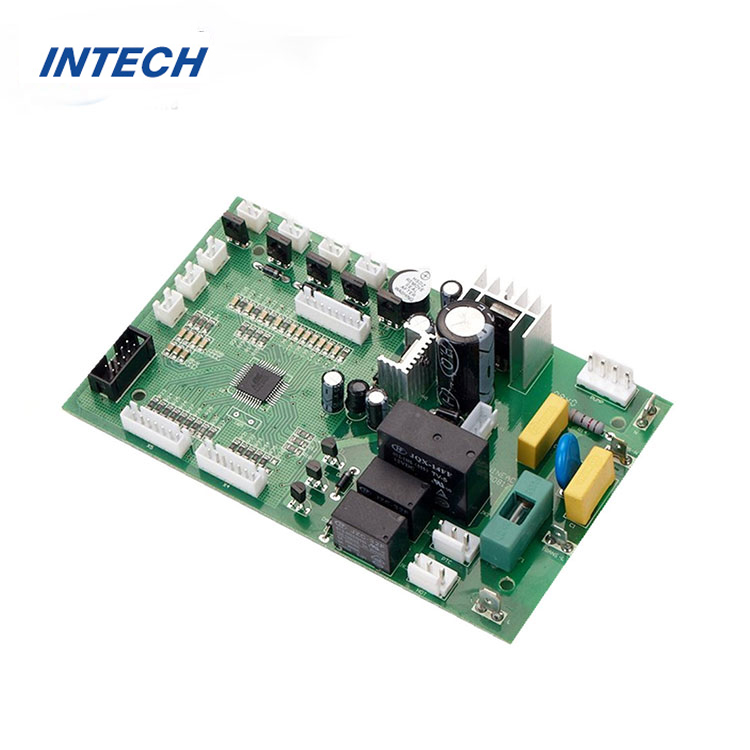

The process of ordering PCB assemblies is crucial in the electronics manufacturing industry. From initial design to final production, there are several steps involved in ensuring that the PCB assemblies meet the required specifications and are delivered on time. This article aims to provide an in-depth understanding of the ordering process, highlighting key aspects and considerations.

1. Identifying the PCB Assembly Requirements

Before placing an order for PCB assemblies, it is essential to identify the specific requirements. This includes the desired functionality, the desired number of layers, dimensions, materials, and any special features or components. Gathering all the necessary information upfront will ensure a smooth ordering process and prevent delays or errors.

2. Choosing a Reliable PCB Manufacturer

Selecting a reputable PCB manufacturer is crucial for ensuring the delivery of high-quality assemblies. Conducting thorough research, checking reviews, and comparing different manufacturers will help in making an informed decision. Factors to consider include manufacturing capabilities, certifications, quality control processes, and customer support.

3. Sending the PCB Design Files

Once a manufacturer is chosen, the next step is to send the PCB design files. These files typically include Gerber files, bill of materials (BOM), and any specific instructions or drawings. It is essential to ensure that the files are accurate and well-documented to prevent any errors during the manufacturing process.

4. Design for Manufacturability (DFM) Review

After receiving the design files, the manufacturer conducts a Design for Manufacturability (DFM) review. This involves a thorough analysis of the design to identify potential manufacturing issues, such as spacing errors, incomplete layers, or component placement problems. The DFM review ensures that the design can be manufactured efficiently and without any significant issues.

5. Quotation and Approval

Based on the DFM review, the manufacturer provides a quotation for the PCB assemblies. The quotation typically includes the cost per unit, manufacturing lead time, and any additional services or customization required. Once the quotation is approved, a purchase order is placed, and production of the PCB assemblies begins.

6. Manufacturing and Assembly

During the manufacturing and assembly process, the PCB manufacturer follows the approved design files and specifications. This includes sourcing the necessary components, fabricating the different layers of the PCB, and soldering the components onto the board. Quality control measures, such as automated optical inspection (AOI) and functional testing, are carried out to ensure the assemblies meet the required standards.

7. Packaging and Delivery

Once the PCB assemblies are manufactured and tested, they go through the final packaging process. This includes proper anti-static packaging and labeling for easy identification. The manufacturer then arranges for secure and timely shipping, taking into consideration any specific shipping requirements or protocols.

Conclusion

The process of ordering PCB assemblies involves several crucial steps, starting from identifying the requirements to the final delivery. By understanding and following each step carefully, electronics manufacturers can ensure the production of high-quality PCB assemblies that meet customer expectations and specifications.