Maintenance and maintenance of aluminum PCB

Date:2023-06-15 11:57:51

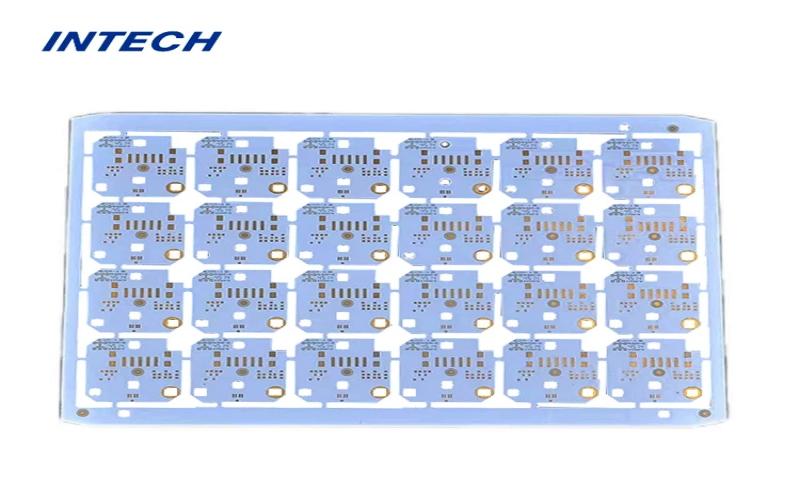

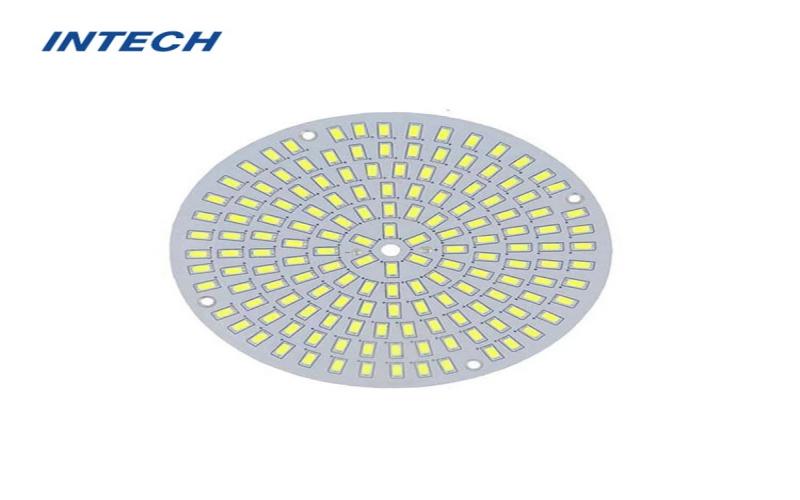

Heat dissipation performance of aluminum PCB Aluminum-based printed circuit board (Aluminum Printed Circuit Board, referred to as aluminum PCB) is a printed circuit board with aluminum-based materials as the substrate. Compared with traditional FR4 PCB, aluminum PCB has better heat dissipation performance, so it is widely used in many high-power electronic devices. In this article, we will discuss the heat dissipation performance of aluminum PCB and its important role in the field of electronics.

First of all, aluminum PCB has good thermal conductivity. Aluminum is an excellent heat-conducting material, and its thermal conductivity is much higher than that of common FR4 materials. This means that the aluminum PCB can conduct the heat generated by the electronic device to the surrounding environment faster, thereby effectively reducing the operating temperature of the electronic device. This is especially important for high-power electronic equipment, because excessively high operating temperatures can cause performance degradation or even damage to electronic devices.

Secondly, aluminum PCB has a larger heat dissipation area. Compared with traditional FR4 PCB, aluminum PCB usually has a larger heat dissipation area. This is because the aluminum-based material of the aluminum PCB can increase the heat dissipation area through milling, drilling and other processing techniques. A larger heat dissipation area means more heat can be dissipated to the surrounding environment through radiation, convection and conduction, thereby improving the heat dissipation effect. In addition, aluminum PCB can also be used in combination with other heat dissipation materials to further improve heat dissipation performance. For example, aluminum PCBs can be combined with heat sinks, heat sinks and other components to form a more complete heat dissipation system. This combination can increase the heat dissipation area and improve heat conduction efficiency, and can be designed and customized according to specific needs to meet the heat dissipation requirements of different electronic devices.

The good heat dissipation performance of aluminum PCB plays an important role in the electronic field. First, it can improve the reliability and lifetime of electronic devices. By lowering the operating temperature, aluminum PCBs can reduce thermal stress on electronic devices, thereby slowing down the rate of device aging and damage. Secondly, good heat dissipation performance can improve the working efficiency of electronic devices. Excessively high operating temperature will lead to performance degradation of electronic devices, and through effective heat dissipation, devices can be kept working at a lower temperature to improve their performance and stability. In practical application, we need to pay attention to some details to maximize the heat dissipation performance of aluminum PCB. First of all, a reasonable heat dissipation design is crucial. We need to select the appropriate aluminum PCB thickness, heat dissipation area and heat dissipation structure according to the specific electronic equipment and heat dissipation requirements. Secondly, the selection of good heat dissipation materials and heat dissipation components is also key. We can choose materials such as silica gel with high thermal conductivity, heat dissipation paste, and components such as efficient heat sinks and heat sinks to further improve the heat dissipation effect.

In short, aluminum PCB has good heat dissipation performance, which can effectively reduce the operating temperature of electronic devices and improve their reliability and performance. In the field of electronics, rational use of the heat dissipation characteristics of aluminum PCBs for heat dissipation design and optimization is of great significance for ensuring the normal operation and long-term use of electronic equipment.