The role and importance of PCB processing edge

Date:2023-11-20 10:33:31

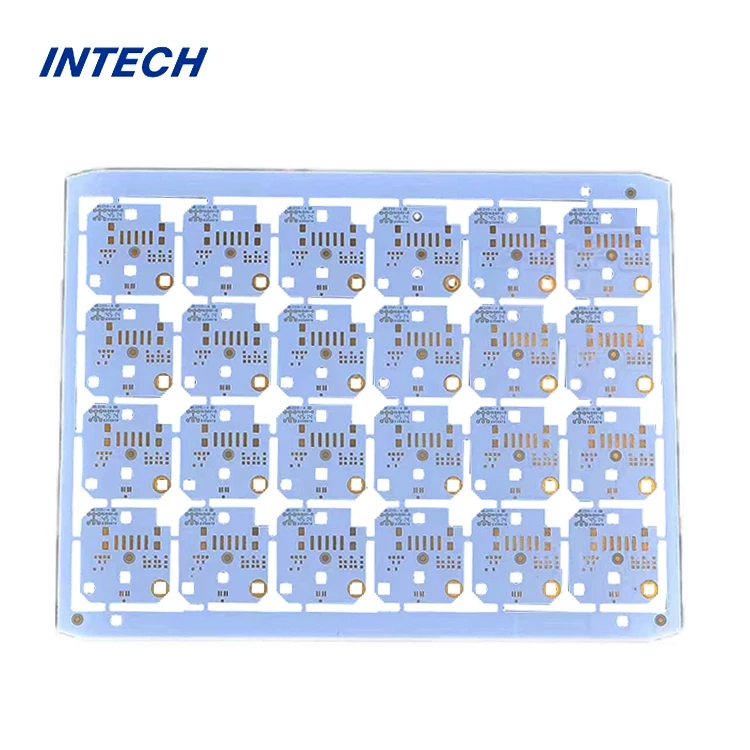

In the world of electronics manufacturing, the role and importance of PCB (Printed Circuit Board) processing edge cannot be overstated. The processing edge of a PCB refers to the perimeter of the board where all the components and traces are located. This article delves into the significance of the PCB processing edge and highlights its diverse applications in various industries.

1. Enhancing Electrical Performance

The edge of a PCB plays a crucial role in ensuring the electrical performance of the circuit. It provides a solid ground for efficient signal transmission and reduces electromagnetic interference. The processing edge also helps in maintaining the integrity of the circuitry and prevents signal loss. By carefully designing the edge, engineers can optimize the electrical performance of the PCB.

2. Improving Mechanical Stability

Another vital aspect of PCB processing edge is its contribution to the mechanical stability of the board. The edge serves as a support structure, holding all the components together. It prevents flexing or bending, thereby ensuring the longevity and reliability of the circuit board. Proper processing edge design adds strength and rigidity to the PCB, making it resistant to external stress and environmental factors.

3. Facilitating Efficient Assembly

The processing edge of a PCB greatly aids in the assembly process. It provides a clear visual reference point for PCB manufacturers and assemblers, allowing them to align and mount components accurately. The edge also facilitates automated assembly processes, such as pick-and-place machines, by providing a reliable boundary that guides the precise placement of components. This results in faster and more efficient assembly, reducing time and cost in production.

4. Enabling Unique Board Shapes

The processing edge of a PCB opens up possibilities for unique and unconventional board shapes. This is particularly beneficial in the design and development of specialized electronics, where standard rectangular boards may not suffice. By customizing the edge shape, designers can create PCBs that fit specific enclosures or conform to ergonomic requirements. The flexibility in board shape made possible by the processing edge allows for innovative product designs.

5. Ensuring PCB Security

The processing edge of a PCB also plays a vital role in ensuring the security of the circuitry. By incorporating a secure edge design, the board becomes less susceptible to tampering or unauthorized access. This is particularly important in applications where sensitive data or intellectual property is involved. The processing edge can be designed to include features like tamper-evident seals or secure mounting mechanisms to prevent unauthorized removal or tampering of components.

6. Supporting Advanced Technologies

The ever-evolving field of electronics demands PCBs that can support advanced technologies. The processing edge enables the integration of high-density components, allowing for miniaturization and increased functionality. It also facilitates the implementation of advanced manufacturing techniques, such as chip-on-board (COB) or wire bonding. The processing edge acts as a foundation for advanced technologies, ensuring PCBs keep up with the demands of emerging electronic applications.

Summary

The PCB processing edge plays a multifaceted role in the world of electronics manufacturing. From enhancing electrical performance and mechanical stability to enabling unique board shapes and supporting advanced technologies, its importance cannot be overstated. By understanding the significance of the processing edge, designers and manufacturers can optimize PCB performance, improve assembly processes, and ensure the security and functionality of electronic devices.