What does PCB assembly involve in electronics manufacturing?

Date:2023-11-24 09:58:15

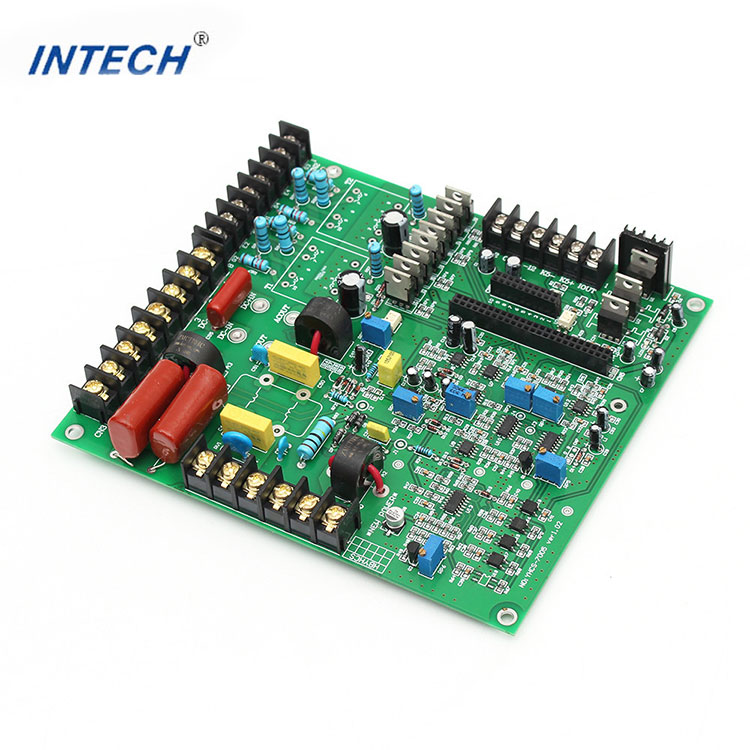

PCB assembly, also known as Printed Circuit Board assembly, is a crucial step in the manufacturing of electronic devices. It involves the process of assembling various electronic components onto a PCB to create a functional circuit. This comprehensive guide will provide a detailed overview of the PCB assembly process and its significance in electronics manufacturing.

1. Introduction to PCB Assembly

PCB assembly is a complex process that entails multiple stages and requires careful attention to detail. It involves the precise placement and soldering of electronic components onto the PCB. This process forms the backbone of virtually every electronic device, from smartphones and computers to medical devices and automotive electronics.

2. PCB Design and Prototyping

Before manufacturing a PCB, it undergoes a design and prototyping phase. This involves creating a schematic diagram of the circuit and designing the layout of the PCB. Computer-aided design (CAD) software is commonly used to create the design. Once the design is finalized, a prototype PCB is produced to ensure its functionality and optimize its design before mass production.

3. Component Procurement

The next step in PCB assembly is procuring the necessary electronic components for the circuit. This involves sourcing components from reliable suppliers and ensuring their compatibility with the PCB design. Components can vary from simple resistors and capacitors to more advanced integrated circuits (ICs) and microprocessors. Quality control is crucial to ensure the reliability and performance of the final product.

4. Surface Mount Technology (SMT) Assembly

Surface Mount Technology (SMT) is the most common method used for PCB assembly. In this process, electronic components are mounted directly onto the surface of the PCB. SMT assembly offers numerous benefits, including higher component density, improved electrical performance, and cost-effectiveness. Automated machines, known as pick-and-place machines, are used to precisely position and solder the components onto the PCB.

5. Through-Hole Assembly

While SMT assembly is widely used, there are cases where through-hole assembly is necessary. Through-hole assembly involves inserting leads of electronic components through pre-drilled holes on the PCB and soldering them on the opposite side. This method is commonly used for components requiring higher mechanical strength or higher power dissipation. Through-hole assembly is typically done using automated machines or manual soldering depending on the production volume and complexity.

6. Quality Control and Testing

After the PCB assembly process is complete, thorough quality control measures are implemented to ensure the functionality and reliability of the final product. Comprehensive testing methods, including functional testing, boundary scan testing, and in-circuit testing, are employed to identify any potential defects or faults. Quality control processes play a critical role in ensuring that only high-quality PCBs are dispatched for further processing or delivered to customers.

Conclusion

PCB assembly is a fundamental process in electronics manufacturing. It involves various stages, including design, component procurement, surface mount and through-hole assembly, and quality control. Each step contributes to the creation of functional and reliable electronic devices. The intricacy and precision required in the PCB assembly process highlight its significance in the electronics industry.