What are the various advantages of rigid PCB?

Date:2024-03-12 02:36:04

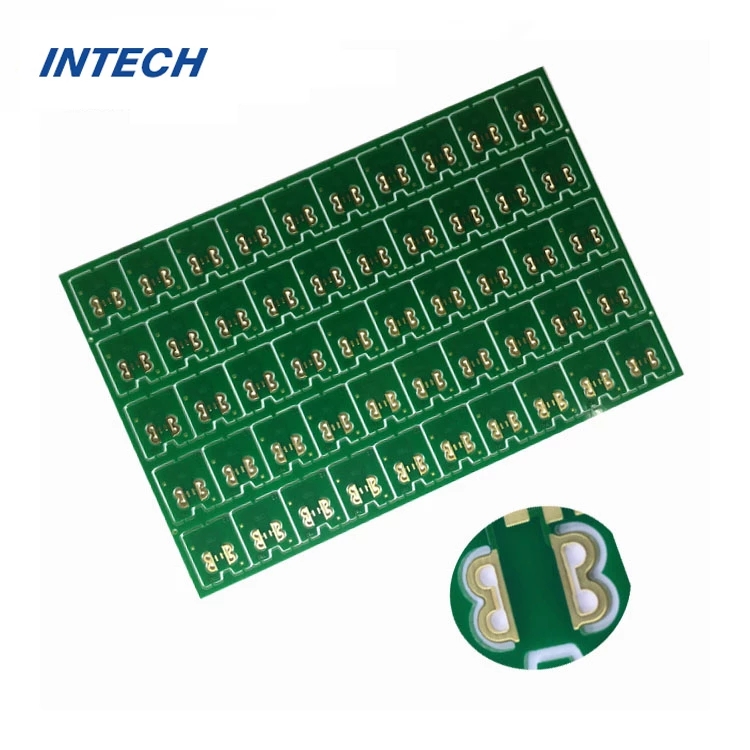

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, providing a platform for the interconnection of electronic components. Among the various types of PCBs available, rigid PCBs stand out for their durability, reliability, and versatility. In this article, we will delve into the numerous advantages of rigid PCBs, including their use in various applications, their manufacturing process, and the benefits they offer to industries and consumers.

1. Introduction to Rigid PCBs:

Rigid PCBs, also known as rigid printed circuit boards, are constructed using a solid substrate material that provides rigidity and stability to the board. Unlike flexible or rigid-flex PCBs, which offer flexibility, rigid PCBs maintain a fixed shape and are commonly used in applications where stability and durability are paramount.

2. Key Advantages of Rigid PCBs:

a. Structural Stability: One of the primary advantages of rigid PCBs is their structural stability. The solid substrate material used in rigid PCBs ensures that the board maintains its shape and integrity, even when subjected to mechanical stress or environmental factors such as temperature fluctuations or humidity.

b. High Component Density: Rigid PCBs are capable of supporting a high component density, allowing for the integration of numerous electronic components onto a single board. This makes them ideal for applications where space is limited, such as in consumer electronics, telecommunications equipment, and industrial control systems.

c. Enhanced Durability: Rigid PCBs are renowned for their durability and resistance to mechanical stress, vibration, and impact. The solid substrate material provides a robust foundation for mounting electronic components, ensuring long-term reliability and performance even in harsh operating conditions.

d. Ease of Assembly: Rigid PCBs offer ease of assembly and manufacturing, thanks to their rigid structure and standardized design. Components can be easily soldered onto the board using automated assembly processes, reducing production time and costs.

e. Electrical Performance: Rigid PCBs provide excellent electrical performance, with low signal loss and impedance matching capabilities. This ensures reliable signal transmission and minimal interference, making them suitable for high-speed data communication and signal processing applications.

f. Multilayer Configurations: Rigid PCBs can be configured into multilayer designs, with multiple layers of conductive traces separated by insulating layers. This allows for increased routing flexibility, reduced signal crosstalk, and improved thermal management, making them suitable for complex electronic systems.

g. Cost-Effectiveness: Despite their numerous advantages, rigid PCBs remain cost-effective compared to other types of PCBs such as flexible or rigid-flex boards. Their standardized manufacturing processes and widespread availability of substrate materials contribute to their affordability.

3. Applications of Rigid PCBs:Rigid PCBs find applications across a wide range of industries, including:

- Consumer Electronics: Rigid PCBs are used in devices such as smartphones, laptops, tablets, and gaming consoles.

- Automotive Electronics: Rigid PCBs are integral components of automotive systems, including engine control units, infotainment systems, and dashboard displays.

- Industrial Automation: Rigid PCBs are utilized in industrial control systems, robotics, and manufacturing equipment.

- Aerospace and Defense: Rigid PCBs are employed in avionics, navigation systems, radar systems, and military-grade electronics.

- Medical Devices: Rigid PCBs are used in medical imaging equipment, patient monitoring devices, and diagnostic instruments.

In conclusion, rigid PCBs offer a host of advantages, including structural stability, high component density, enhanced durability, ease of assembly, excellent electrical performance, multilayer configurations, and cost-effectiveness. These advantages make them indispensable components in a wide range of electronic devices and systems across various industries. As technology continues to advance, the demand for rigid PCBs is expected to grow, driven by innovations in electronics, telecommunications, automotive, aerospace, and other sectors.