What are the two different types of rigid PCB?

Date:2024-03-12 02:35:48

Printed Circuit Boards (PCBs) serve as the foundation of electronic devices, providing a platform for the interconnection of electronic components. Among the various types of PCBs available, rigid PCBs are widely used due to their durability, reliability, and versatility. In this article, we will explore the two main types of rigid PCBs, their characteristics, applications, and the factors to consider when purchasing them, with a focus on sourcing from China.

1. Single-Layer Rigid PCBs:Single-layer rigid PCBs, also known as single-sided PCBs, consist of a single layer of conductive material (usually copper) laminated onto a rigid substrate material such as fiberglass (FR4). The conductive layer is etched to create a circuit pattern, and components are mounted on one side of the board.

Characteristics:

- Simplest and most cost-effective type of PCB.

- Suitable for basic electronic applications with minimal complexity.

- Limited routing flexibility due to the single-layer design.

- Commonly used in consumer electronics, toys, lighting fixtures, and household appliances.

Applications:

- LED lighting systems

- Remote controls

- Calculators

- Printed sensors

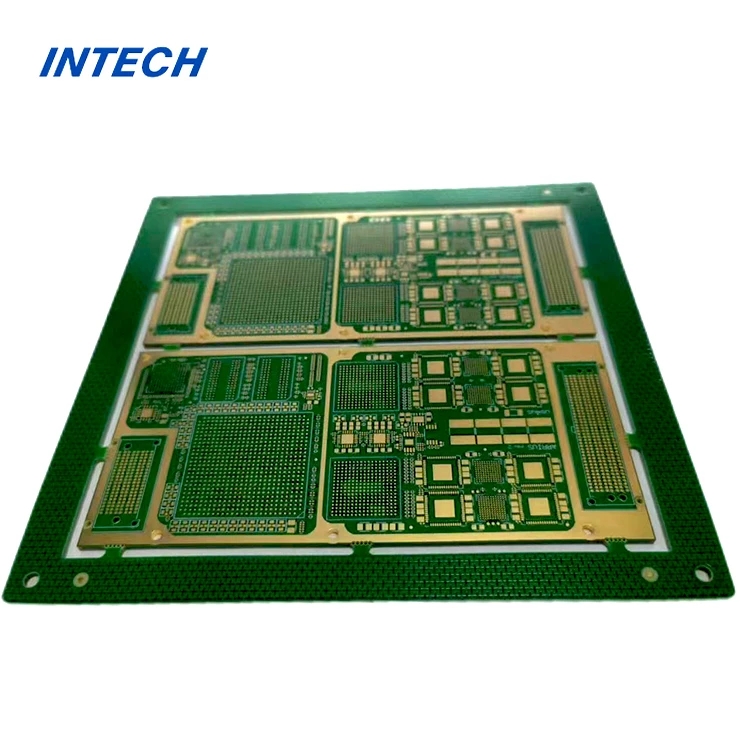

2. Multilayer Rigid PCBs:Multilayer rigid PCBs consist of multiple layers of conductive material separated by insulating layers (prepreg). The conductive layers are interconnected through plated through-holes (PTHs) or vias, allowing for complex circuit designs and increased routing flexibility.

Characteristics:

- More complex and versatile than single-layer PCBs.

- Can accommodate a higher component density and more intricate circuit designs.

- Provide better signal integrity and reduced electromagnetic interference (EMI).

- Suitable for applications requiring high performance and reliability.

Applications:

- Computer motherboards

- Networking equipment

- Medical devices

- Automotive electronics

Industrial control systems

Factors to Consider When Buying Rigid PCBs from China:

a. Quality Assurance: When sourcing rigid PCBs from China, it is essential to ensure that the supplier adheres to international quality standards such as ISO, UL, and IPC. Verify the supplier's certifications and quality control processes to guarantee the reliability and performance of the PCBs.

b. Manufacturing Capabilities: Choose a supplier with state-of-the-art manufacturing facilities and advanced equipment to ensure the production of high-quality rigid PCBs. Inquire about the supplier's production capacity, lead times, and ability to handle custom requirements.

c. Technical Support: Opt for a supplier that offers comprehensive technical support and engineering expertise to assist with PCB design, prototyping, and optimization. Effective communication and collaboration with the supplier can streamline the manufacturing process and ensure the desired results.

d. Cost Competitiveness: Compare quotes from different China-based rigid PCB suppliers to find a balance between quality and cost. Consider factors such as production volume, complexity of the design, and additional services (e.g., assembly, testing) offered by the supplier.

e. Environmental Compliance: Verify that the PCB supplier complies with environmental regulations and standards, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals). Ensure that the materials used in PCB manufacturing are environmentally friendly and sustainable.

Conclusion:In conclusion, rigid PCBs come in two main types: single-layer and multilayer, each with its own characteristics, applications, and considerations. When buying rigid PCBs from China, it is crucial to prioritize factors such as quality assurance, manufacturing capabilities, technical support, cost competitiveness, and environmental compliance. By partnering with a reliable and reputable China-based rigid PCB supplier, businesses can access high-quality PCBs that meet their specifications and requirements, thereby ensuring the success of their electronic projects and products.