Are flex rigid PCBs more durable than traditional PCB?

Date:2024-03-12 02:47:37

The durability of printed circuit boards (PCBs) is a crucial factor in determining their reliability and suitability for various applications. With the advancement in technology, flex rigid PCBs have emerged as an alternative to traditional PCBs, offering improved flexibility and reliability. This article aims to explore and compare the durability of flex rigid PCBs with their traditional counterparts.

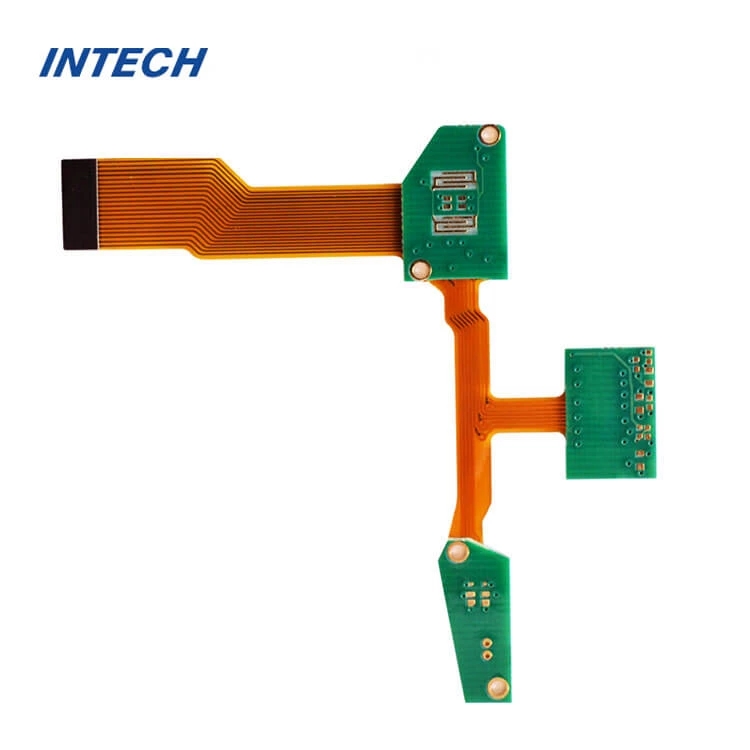

1. Introduction to flex rigid PCBs

Flex rigid PCBs, also known as flexible-rigid printed circuit boards, are a hybrid solution that combines the benefits of both flexible and rigid PCBs. These boards consist of a combination of flexible and rigid substrates, allowing for increased freedom in designing complex circuitry.

2. Enhanced resistance to mechanical stress

One of the primary reasons why flex rigid PCBs are considered more durable than traditional PCBs is their enhanced resistance to mechanical stress. The combination of flexible and rigid materials in these boards provides excellent resistance against bending, twisting, and other forms of physical stress. This makes them ideal for applications that involve frequent movement or vibration, such as automotive electronics or wearable devices.

3. Improved reliability in harsh environments

Flex rigid PCBs offer improved reliability in harsh operating environments. The combination of flexible materials with excellent temperature resistance allows these boards to withstand extreme temperatures, high humidity, and exposure to chemicals. Additionally, the integration of rigid sections provides better protection for sensitive components, reducing the risk of damage caused by environmental factors.

4. Enhanced signal integrity

Signal integrity is critical in electronic devices, as it ensures the proper functioning of circuits and reduces the chances of data loss or corruption. Flex rigid PCBs exhibit better signal integrity compared to traditional PCBs due to their minimized signal loss, impedance control, and reduced electromagnetic interference (EMI). This makes them suitable for high-speed and high-frequency applications, such as telecommunications or aerospace electronics.

5. Improved assembly and space utilization

Flex rigid PCBs offer improved assembly and space utilization capabilities. The flexibility of these boards allows for compact and intricate designs, enabling the integration of more components within a smaller footprint. This not only reduces the overall size of the electronic device but also enhances its durability by minimizing the risks associated with loose or disconnected components.

Conclusion

In conclusion, flex rigid PCBs are indeed more durable than traditional PCBs. Their enhanced resistance to mechanical stress, improved reliability in harsh environments, better signal integrity, and improved assembly capabilities make them a viable choice for various applications. The versatility and durability offered by flex rigid PCBs make them an ideal solution for industries requiring flexible and reliable circuitry.