How is quality ensured in pcb assembly services?

Date:2024-03-28 00:24:27

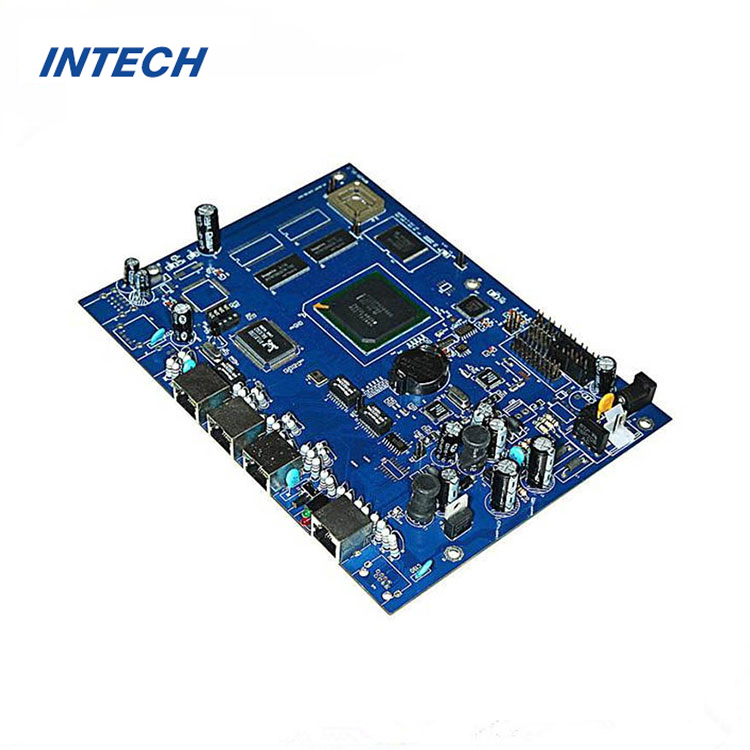

PCB assembly services play a crucial role in the manufacturing of electronic devices, providing the expertise and infrastructure needed to assemble complex printed circuit boards (PCBs) with precision and reliability. Quality assurance is paramount in PCB assembly services to ensure that the assembled PCBs meet the highest standards of performance, reliability, and safety. In this article, we'll explore how quality is ensured in PCB assembly services, covering key processes, methodologies, and considerations.

Introduction to Quality Assurance in PCB Assembly Services

Quality assurance in PCB assembly services involves implementing rigorous processes, procedures, and controls at every stage of the assembly process to detect and prevent defects, ensure compliance with specifications, and meet customer requirements. By adhering to industry standards, best practices, and quality management systems, PCB assembly services can consistently deliver high-quality assemblies that meet the needs of various industries and applications.

Key Elements of Quality Assurance in PCB Assembly Services

Component Verification: The quality assurance process begins with thorough verification of electronic components to ensure that they meet the specified requirements in terms of quality, reliability, and compatibility with the PCB design. Component verification includes checking datasheets, certifications, and traceability information to confirm authenticity and compliance with regulatory standards.

Assembly Process Control: PCB assembly services employ advanced manufacturing equipment and technologies to control and monitor the assembly process. Automated pick-and-place machines, solder paste dispensers, reflow ovens, and inspection systems are used to ensure consistency, accuracy, and repeatability in component placement, soldering, and inspection.

Soldering Quality: Soldering is a critical process in PCB assembly that requires precise control to ensure the formation of reliable solder joints. Quality assurance measures such as solder paste inspection (SPI), automated optical inspection (AOI), and X-ray inspection are used to detect defects such as solder bridging, insufficient solder, and misalignment.

Inspection and Testing: Comprehensive inspection and testing are conducted throughout the assembly process to verify the quality and integrity of the assembled PCBs. Visual inspection, electrical testing, functional testing, and environmental testing are performed to detect defects, ensure functionality, and validate performance under various operating conditions.

Quality Management Systems: PCB assembly services implement robust quality management systems (QMS) to document, track, and manage quality-related processes and activities. Quality management systems include procedures for risk management, corrective and preventive actions (CAPA), nonconformance management, and continuous improvement to drive excellence and customer satisfaction.

Regulatory Compliance: Compliance with industry standards and regulatory requirements, such as IPC (Association Connecting Electronics Industries) standards and RoHS (Restriction of Hazardous Substances) directives, is essential for ensuring the safety, reliability, and environmental sustainability of PCB assemblies. PCB assembly services adhere to relevant standards and regulations to meet customer expectations and legal obligations.

Supplier Quality Management: Effective supplier quality management is critical in ensuring the availability and consistency of high-quality components and materials for PCB assembly. PCB assembly services work closely with suppliers to establish quality criteria, monitor performance, and address any issues or concerns that may impact the quality of the final product.

Continuous Improvement and Customer Satisfaction

Continuous improvement is a core principle of quality assurance in PCB assembly services. By collecting and analyzing data, identifying areas for improvement, and implementing corrective actions, PCB assembly services strive to enhance efficiency, reduce defects, and exceed customer expectations. Customer feedback and satisfaction are integral to the continuous improvement process, driving innovation and excellence in PCB assembly services.

In conclusion, quality assurance is paramount in PCB assembly services to ensure that assembled PCBs meet the highest standards of performance, reliability, and safety. By implementing rigorous processes, controls, and quality management systems, PCB assembly services can consistently deliver high-quality assemblies that meet customer requirements and industry standards. Through continuous improvement and a commitment to excellence, PCB assembly services play a vital role in the success of electronic devices across various industries and applications.