How do PCB assembly manufacturers ensure quality control?

Date:2024-05-22 17:36:21

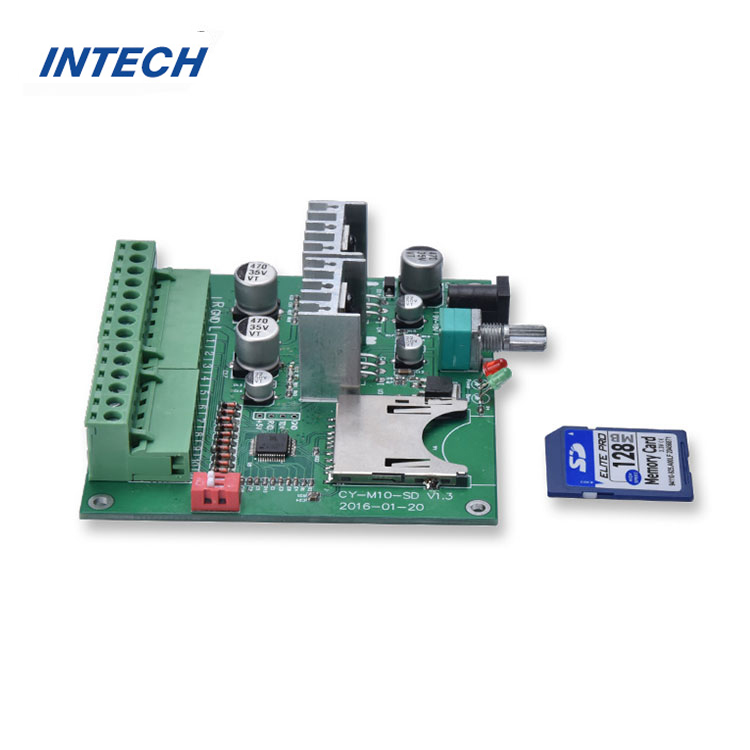

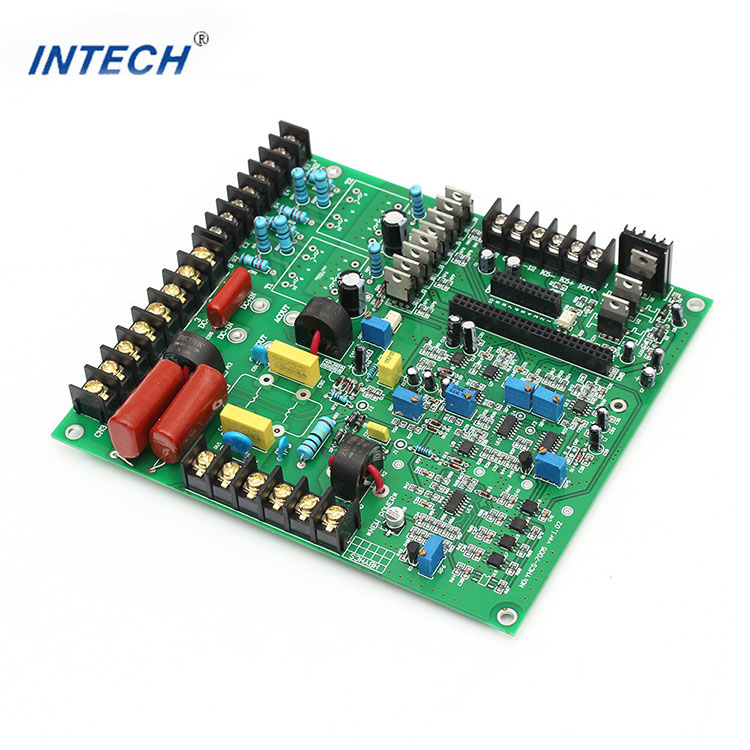

In the intricate world of PCB (Printed Circuit Board) assembly manufacturing, the assurance of quality control is paramount. With the ever-increasing complexity of electronic components and the critical role that PCBs play in a myriad of devices, from consumer electronics to industrial machinery, maintaining high standards of quality throughout the manufacturing process is essential. In this comprehensive article, we delve into the methodologies employed by PCB assembly manufacturers to ensure meticulous quality control at every stage of production.

1. Advanced Inspection Technologies

One of the primary methods through which PCB board assembly manufacturers ensure quality control is by leveraging advanced inspection technologies. Automated Optical Inspection (AOI) systems, equipped with high-resolution cameras and sophisticated algorithms, play a pivotal role in scrutinizing solder joints, component placement accuracy, and overall PCB integrity. Additionally, X-ray inspection equipment enables manufacturers to delve deeper, inspecting hidden solder connections and identifying potential defects such as voids or misalignments that may compromise the integrity of the final product.

2. Statistical Process Control (SPC)

Implementing Statistical Process Control (SPC) methodologies is another cornerstone of quality control in PCB board assembly manufacturing. By closely monitoring key process parameters in real-time, such as solder paste viscosity, component alignment, and reflow oven temperature profiles, manufacturers can detect deviations from established norms and take corrective action promptly. This data-driven approach to quality control enables manufacturers to identify trends, mitigate process variations, and enhance overall process stability.

3. Quality Management Systems (QMS)

Adherence to rigorous Quality Management Systems (QMS) is essential for ensuring consistent quality across all facets of PCB assembly manufacturing. Standards such as ISO 9001 or IPC-A-610 provide comprehensive frameworks encompassing quality assurance protocols, document control, supplier management, process validation, and continuous improvement initiatives. By aligning with internationally recognized QMS standards, PCB assembly manufacturers demonstrate their commitment to delivering products of the highest caliber.

4. Component Verification and Authentication

Ensuring the authenticity and reliability of electronic components is paramount in PCB assemblies manufacturing. Traceability solutions, including barcode labeling, RFID tagging, and serialization, enable manufacturers to track components throughout the supply chain, from procurement to assembly. By maintaining comprehensive traceability records, manufacturers can swiftly identify counterfeit or substandard components, thereby mitigating the risk of product failures and ensuring regulatory compliance.

5. Process Optimization and Continuous Improvement

Optimizing manufacturing processes and embracing continuous improvement initiatives are fundamental to maintaining high standards of quality in PCB assembly manufacturing. Lean manufacturing principles, such as Just-in-Time (JIT) inventory management and cellular manufacturing layouts, facilitate operational efficiency and waste reduction. Additionally, the integration of Six Sigma methodologies empowers manufacturers to systematically identify and eliminate process variations, thereby minimizing defects and enhancing product quality.

Conclusion

Ensuring quality control in PCB assemblies manufacturing is a multifaceted endeavor that requires meticulous attention to detail, advanced technologies, and a commitment to continuous improvement. From leveraging advanced inspection technologies to implementing rigorous quality management systems and optimizing manufacturing processes, PCB assembly manufacturers employ a myriad of methodologies to uphold the highest standards of quality and reliability. By embracing these practices, manufacturers can confidently deliver PCB assemblies that power the technological innovations of today and tomorrow.

If you want to read more information about how to boost traffic on your Website, just visit:https://www.intechcircuit.com