What Makes Aluminum PCBs More Efficient?

Date:2024-05-30 17:16:38

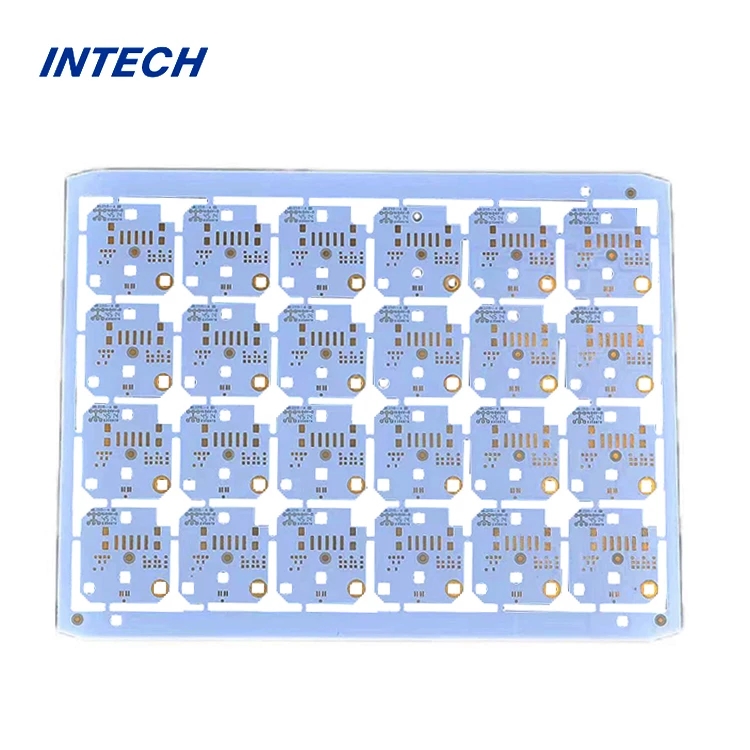

An aluminum printed circuit board is a type of PCB that uses aluminum as the base material instead of the usual fiberglass or plastic. The structure typically consists of an aluminum base, a dielectric layer, and a copper circuit layer. This composition offers several benefits that enhance the performance and durability of electronic devices.This article will explore the factors that make aluminum PCBs more efficient and highlight the role of aluminum PCB manufacturers and factories in producing these high-performance components.

1. Superior Thermal Conductivity

One of the key advantages of aluminum PCBs is their superior thermal conductivity compared to traditional FR-4 materials. Aluminum is an excellent conductor of heat, which allows for more effective heat dissipation in electronic devices. This property is crucial for maintaining the performance and longevity of sensitive electronic components, particularly in high-power applications.

2. Enhanced Structural Integrity

Aluminum PCBs offer enhanced structural integrity due to the strength and rigidity of aluminum. This makes them ideal for applications where the PCB may be subjected to mechanical stress or vibration. The robustness of aluminum PCBs ensures that they can withstand harsh conditions without compromising the integrity of the circuitry.

3. Lightweight and Cost-Effective

Aluminum is lighter than many materials traditionally used in PCB construction, such as copper-clad laminates. This lightweight property can be beneficial for applications where weight is a critical factor, such as in aerospace or portable electronics. Additionally, aluminum is more cost-effective than some other materials, making aluminum PCBs an economically viable option for manufacturers.

4. Improved EMI and RFI Shielding

Aluminum PCBs provide better electromagnetic interference (EMI) and radio frequency interference (RFI) shielding compared to other PCB materials. This is particularly important in applications where signal integrity is crucial, such as in communication devices or medical equipment. The inherent shielding properties of aluminum help to minimize interference and ensure clear signal transmission.

5. The Role of Aluminum PCB Manufacturers and Factories

Aluminum PCB manufacturers and factories play a pivotal role in the production of these efficient components. They are equipped with the latest technology and expertise to fabricate high-quality aluminum printed circuits. These manufacturers are responsible for:

Innovation: Continuously researching and developing new techniques to improve the performance and capabilities of aluminum PCBs.

Quality Control: Ensuring that each aluminum PCB meets stringent quality standards through rigorous testing and inspection processes.

Customization: Offering customization services to meet the specific needs of clients, from size and shape to specialized features.Support and Service: Providing ongoing support and service to clients, including technical assistance, maintenance, and troubleshooting.

Aluminum PCBs offer a range of benefits that contribute to their efficiency, making them an excellent choice for a variety of electronic applications. From superior thermal conductivity and enhanced structural integrity to lightweight properties and improved EMI/RFI shielding, aluminum printed circuits provide a solid foundation for high-performance electronic devices. The expertise and capabilities of aluminum PCB manufacturers and factories are essential in bringing these efficient components to market, ensuring that they meet the high standards required by the electronics industry. As technology continues to advance, the role of aluminum PCBs in driving innovation and efficiency in electronic design is expected to grow.