PCB Assembly Manufacturer Solutions for Rapid Prototyping

Date:2024-10-16 10:14:14

In today's fast-paced electronics industry, rapid prototyping is critical for developing innovative products that meet ever-changing consumer demands. Partnering with a reliable pcb assembly manufacturer plays a key role in accelerating product development cycles, from concept to production. This article explores the essential solutions provided by pcb assembly manufacturers to support rapid prototyping and how their expertise in pcb design services, pcb manufacturing assembly, and pcb board manufacturing can drive innovation.

1. Streamlining the Prototyping Process with PCB Assembly Manufacturers

A pcb assembly manufacturer can offer end-to-end solutions to simplify the rapid prototyping process. These manufacturers work closely with clients to turn complex PCB designs into functional prototypes, allowing engineers to test and refine their ideas in real-time. One of the key advantages of working with professional pcb manufacturing assembly providers is their ability to rapidly produce high-quality boards, meeting tight deadlines while maintaining performance standards.

2. Benefits of PCB Design Services in Prototyping

Effective pcb design services are fundamental to the rapid prototyping process. Professional PCB assembly manufacturers often provide in-house pcb design services, helping clients optimize their board layouts and ensure that designs meet both electrical and mechanical requirements. This minimizes errors, reduces costly revisions, and improves the overall efficiency of the prototyping cycle.

3. Advanced Manufacturing Capabilities for Rapid Prototyping

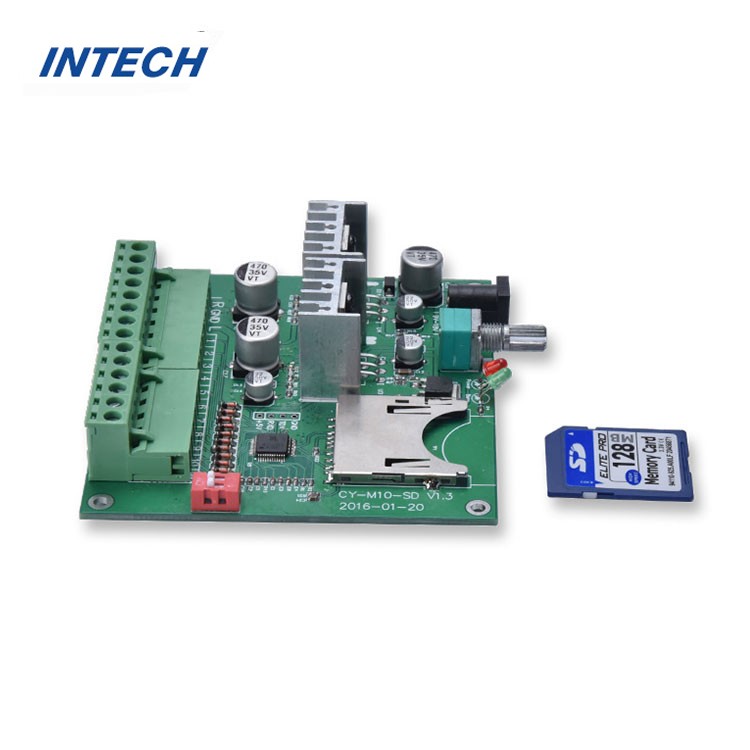

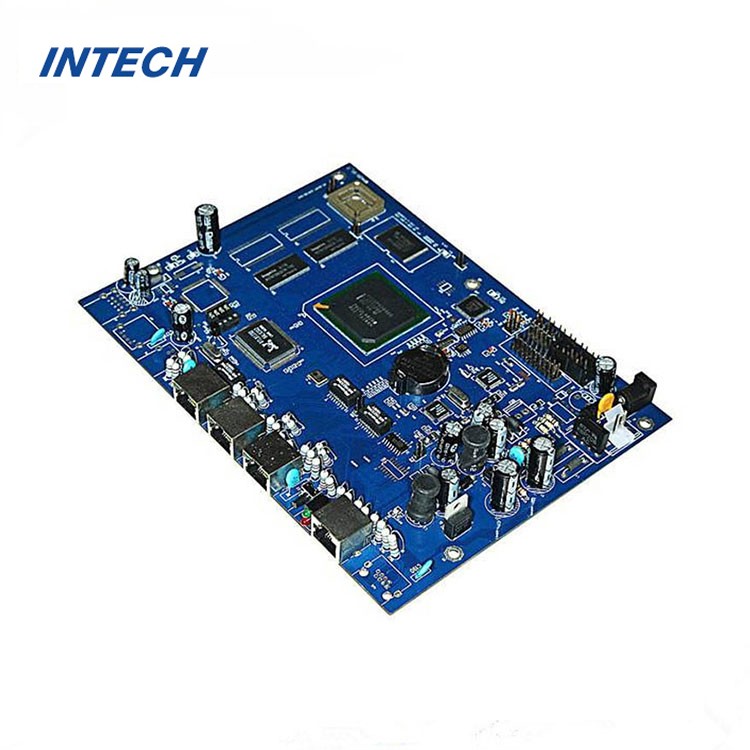

PCB assembly manufacturers offer specialized equipment and techniques to handle the complexities of pcb board manufacturing. Their advanced production facilities can quickly produce small volumes of prototype boards, with capabilities ranging from single-layer to multi-layer PCB assemblies. This flexibility ensures that manufacturers can accommodate different design needs and deliver prototypes that are ready for testing in record time.

4. Testing and Validation in PCB Manufacturing Assembly

Quality is critical in prototyping, and pcb manufacturing assembly providers ensure that every prototype undergoes rigorous testing. From functional testing to automated optical inspection (AOI), these manufacturers validate each board to identify potential issues early on. This ensures that any design flaws are addressed before moving into mass production, saving time and costs in the long run.

5. Cost-Effective PCB Board Manufacturing for Prototypes

Many pcb board manufacturing services also offer cost-effective solutions tailored to prototyping. By optimizing material use, selecting appropriate components, and employing efficient production methods, pcb assembly manufacturers help clients reduce prototyping expenses. This allows companies to experiment with new designs without overextending their budgets.

In the competitive world of electronics, rapid prototyping is essential for bringing innovative products to market quickly. By partnering with an experienced pcb assembly manufacturer offering integrated pcb design services, pcb manufacturing assembly, and pcb board manufacturing solutions, companies can streamline their product development process, enhance quality, and reduce time to market. These partnerships ultimately lead to successful prototypes that pave the way for full-scale production, driving industry growth and technological advancements.