Aluminum PCBs: A Better Solution for Heat Dissipation

Date:2024-09-26 10:27:58

1. What Is an Aluminum PCB?

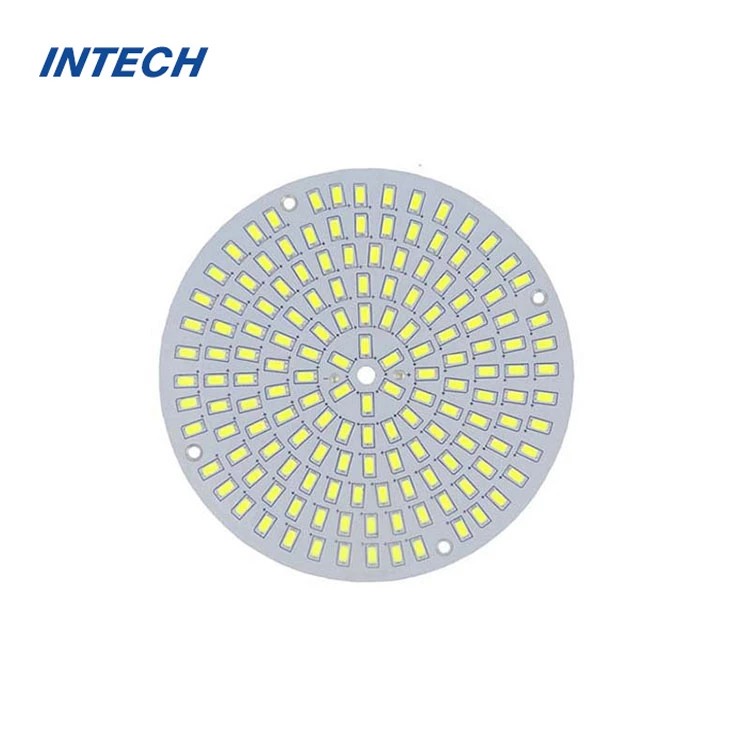

A PCB (Printed Circuit Board) is also known as a printed wiring board. An aluminum PCB is a type of PCB with excellent heat dissipation capabilities, featuring a metal-based copper-clad laminate. Typically, a single-sided aluminum PCB consists of three layers: the circuit layer (copper foil), an insulating layer, and a metal base layer. In some high-end applications, double-sided aluminum PCBs are used, with a structure comprising a circuit layer, insulation layer, aluminum base, another insulation layer, and a second circuit layer. Although rare, multi-layer aluminum PCBs can also be produced by combining regular multi-layer PCBs with insulating layers and aluminum bases.

Single-sided aluminum pcb board: Contains only one conductive pattern layer and an insulating material with an aluminum base.

Double-sided aluminum pcb board: Includes two conductive pattern layers and an insulating material stacked with an aluminum base.

Multi-layer aluminum pcb board: Made of three or more conductive pattern layers and insulating materials, alternated with aluminum bases and laminated together to form a circuit board.

2. How Aluminum PCBs Work ?

Power devices are surface-mounted on the circuit layer, and the heat generated during operation is quickly transferred through the insulation layer to the metal base, which then dissipates the heat. Compared to traditional FR-4 boards, aluminum PCBs minimize thermal resistance, offering excellent thermal conductivity. In comparison to thick-film ceramic circuits, they also provide superior mechanical properties. Additionally, aluminum pcb prototyping offer unique advantages: they are RoHS compliant and well-suited for SMT processes. They handle heat diffusion effectively, lowering operating temperatures, extending lifespan, and improving power density and reliability. Aluminum PCBs also reduce the need for additional hardware like heat sinks, lowering costs and shrinking product size, while offering better mechanical durability than fragile ceramic substrates.

3. Composition of Aluminum PCBs

Circuit Layer: This layer (typically made from electrolytic copper foil) is etched to form the printed circuit for component assembly and connections. With the same thickness and line width, aluminum PCBs can carry higher currents compared to traditional FR-4 boards.

Insulation Layer: The core technology of an aluminum PCB, this layer provides adhesion, insulation, and thermal conductivity. It acts as the main thermal barrier in the power module structure. Better thermal conductivity in the insulation layer allows for faster heat dissipation, lowering the component's operating temperature and boosting power output, reducing size, and extending lifespan.

Metal Base Layer: The choice of metal for the base depends on factors such as the thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface state, and cost.

4. Key Properties of Aluminum PCBs

Heat Dissipation: Many double-sided and multi-layer boards have high density and power, making it difficult to dissipate heat. Conventional PCB materials like FR4 and CEM3 are poor thermal conductors, causing heat buildup that can lead to component failure. Aluminum PCBs solve this issue by providing superior heat dissipation.

Thermal Expansion: Materials naturally expand and contract with temperature changes, and different substances have varying thermal expansion coefficients. Aluminum PCBs help mitigate this issue, reducing the effects of thermal expansion and contraction on components and improving the durability and reliability of electronic devices. This is especially important for addressing thermal expansion in SMT (Surface Mount Technology).

Dimensional Stability: Aluminum pcb prototyping exhibit far greater dimensional stability than conventional insulated PCBs. For example, aluminum PCBs or aluminum sandwich panels show a size change of only 2.5-3.0% when heated from 30°C to 140-150°C.

Aluminum PCBs manufacturers offer excellent performance in terms of heat dissipation, thermal expansion management, and dimensional stability, making them a reliable choice for high-power and high-performance applications.