Why Partner with a PCB Board Assembly Manufacturer?

Date:2024-11-22 11:35:32

In the world of modern electronics, the need for precise and efficient PCB board assembly manufacturing is paramount. From consumer gadgets to industrial machinery, the role of printed circuit boards (PCBs) is crucial in enabling functionality and performance. Partnering with a PCB board assembly manufacturer can be a game-changer for businesses aiming to produce high-quality, reliable electronic devices. Here’s why choosing to collaborate with a professional manufacturer is a smart decision, especially when considering the unique benefits of working with custom PCB assembly factories.

1. Expertise and Technical Knowledge

Professional PCB board assembly manufacturers possess extensive expertise in handling complex assembly processes. They are equipped with skilled technicians and engineers who understand the intricacies of PCB design, assembly, and testing. This technical knowledge ensures that your PCBs are manufactured to meet exact specifications and industry standards. Moreover, experienced manufacturers can offer valuable insights into custom PCB assembly manufacturing, helping you optimize your designs for better performance and cost-efficiency.

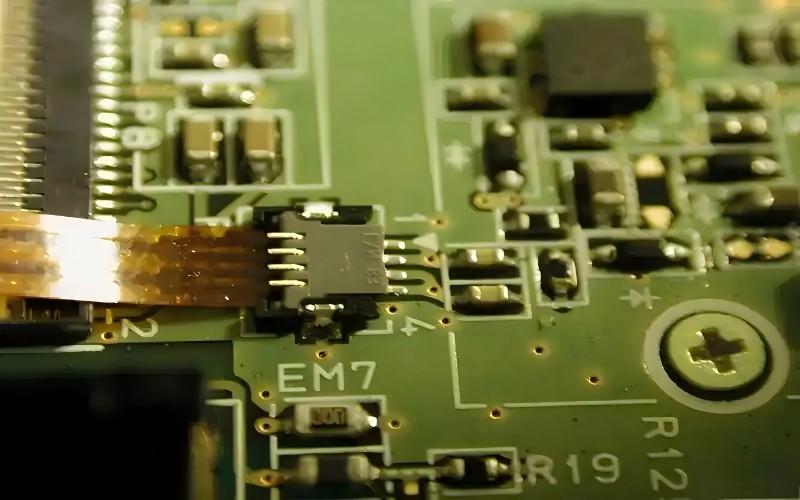

2. Access to Advanced Technology

State-of-the-art technology is a cornerstone of modern PCB board assembly manufacturing. Leading manufacturers invest in advanced equipment such as automated pick-and-place machines, soldering systems, and inspection tools to ensure precision and consistency in every assembly. By partnering with such manufacturers, businesses gain access to these cutting-edge resources without needing to invest in expensive infrastructure themselves. This technological edge is particularly important for companies seeking services from custom PCB assembly factories, as it allows for the production of tailored solutions that meet unique project requirements.

3. Cost and Time Efficiency

Outsourcing your assembly needs to a PCB board assembly manufacturer can save both time and money. Manufacturers streamline the production process by handling everything from sourcing components to assembling and testing the boards. This eliminates the need for businesses to manage multiple suppliers and processes, reducing overhead costs and lead times. Additionally, working with custom PCB assembly factories allows for flexible production volumes, making it easy to scale operations as needed. Whether you require a small batch for prototyping or a large volume for mass production, a trusted manufacturer can deliver efficiently without compromising quality.

4. Guaranteed Quality and Reliability

Quality is a top priority in PCB assembly, as even minor defects can lead to product failures. Reputable PCB board assembly manufacturers implement strict quality control measures at every stage of production. This includes automated optical inspection (AOI), X-ray testing, and functional testing to identify and address issues before delivery. Partnering with a professional manufacturer ensures that your PCBs meet rigorous industry standards, enhancing the reliability and longevity of your final products. For businesses requiring custom PCB assembly manufacturing, this commitment to quality is invaluable in maintaining customer satisfaction and trust.

5. Customization and Flexibility

One of the standout advantages of working with custom PCB assembly factories is the ability to create tailored solutions. Manufacturers specializing in custom assembly can accommodate specific design requirements, such as unique layouts, specialized materials, or unconventional form factors. This flexibility allows businesses to develop innovative products that stand out in the market. Additionally, custom manufacturers can adapt to changes in project scope or requirements, providing the agility needed to meet evolving business goals.

6. Focus on Core Competencies

By outsourcing PCB assembly to a dedicated manufacturer, businesses can focus on their core competencies, such as product design, marketing, and customer support. Letting experts handle the assembly process frees up internal resources and allows teams to concentrate on strategic initiatives that drive growth.

7. Scalability and Support

As businesses grow, so do their production needs. Partnering with a reliable PCB board assembly manufacturer ensures that you have the support required to scale operations seamlessly. Manufacturers can quickly ramp up production volumes while maintaining quality and meeting tight deadlines. Additionally, many manufacturers offer post-assembly support, including maintenance, troubleshooting, and upgrades. This ongoing partnership can be a valuable asset in achieving long-term success.

8. Compliance with Industry Standards

Reputable PCB board assembly manufacturers adhere to strict industry standards and regulations, such as ISO certifications, RoHS compliance, and IPC standards. This ensures that your PCBs are not only high-quality but also meet legal and environmental requirements. For businesses engaging in custom PCB assembly manufacturing, compliance is crucial in avoiding potential legal issues and aligning with global market expectations.

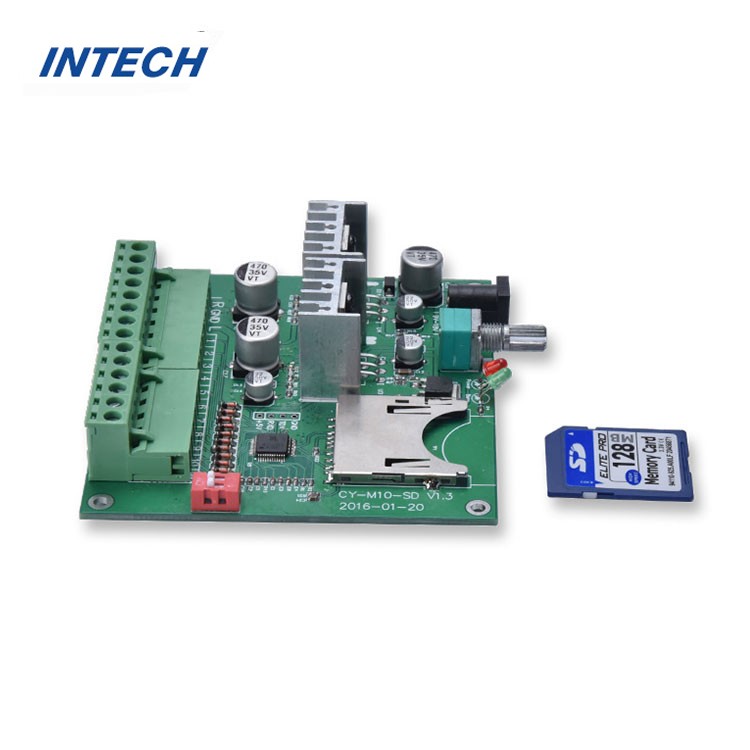

Why Choose Intech for Your PCB Assembly Needs?

At Intech, we understand the challenges and demands of modern PCB assembly. As a leading PCB board assembly manufacturer, we offer end-to-end solutions tailored to your specific requirements. From providing detailed quotes to delivering high-quality custom assemblies, our team is dedicated to ensuring your success.

With our advanced manufacturing facilities, skilled workforce, and commitment to quality, Intech stands out as a trusted partner for all your custom PCB and assembly needs. Whether you’re developing prototypes or scaling up for mass production, we’re here to support you every step of the way.