How to Ensure Quality in Custom Electronic PCB Assembly?

Date:2024-11-22 11:16:13

For companies like Intech, ensuring quality in custom electronic PCB assembly is vital for delivering reliable and high-performing electronic devices. High-quality assembly not only guarantees the functionality of the final product but also builds trust with customers and enhances brand reputation. Here’s how you can ensure top-notch quality in your custom PCB and assembly processes.

1. Partner with Reputable Custom PCB Assembly Factories

Choosing the right custom PCB assembly factories is a critical first step. Reliable manufacturers, like those Intech collaborates with, adhere to strict quality standards, such as ISO certifications and RoHS compliance. Their expertise ensures precision in assembly and reduces the risk of defects, providing the foundation for high-quality products.

2. Use Verified Custom Electronic PCB Assembly Quotes

Obtaining detailed and accurate custom electronic PCB assembly quotes is essential. These quotes should outline all aspects of the process, including material costs, testing procedures, and lead times. Intech ensures transparency in its quotes, enabling you to make informed decisions and anticipate costs without compromising on quality.

3. Implement Stringent Testing Procedures

Quality assurance in custom PCB and assembly relies heavily on rigorous testing protocols. Key tests include:

AOI (Automated Optical Inspection): Detects component placement issues and soldering defects.

Functional Testing: Verifies that the assembled PCB performs as intended.

Environmental Testing: Assesses performance under various temperature and humidity conditions.

Intech incorporates advanced testing technologies to ensure every PCB meets the highest quality standards.

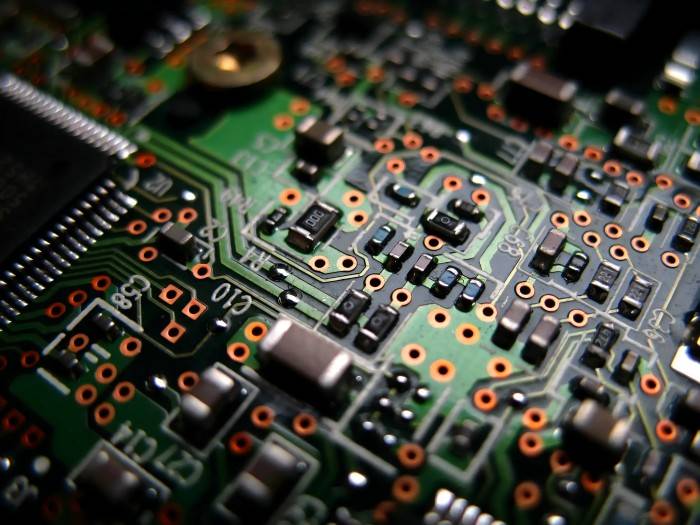

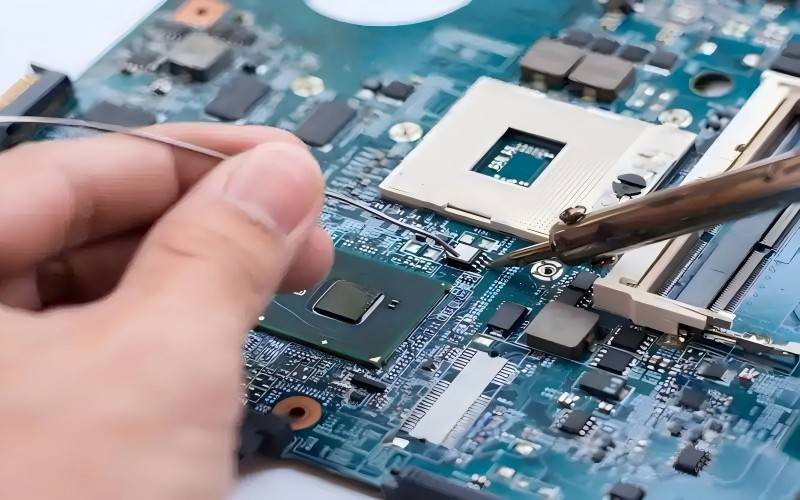

4. Leverage Advanced Equipment and Skilled Workforce

High-quality assembly demands state-of-the-art equipment and a skilled workforce. Leading custom PCB assembly factories utilize advanced SMT (Surface Mount Technology) and THT (Through-Hole Technology) for precise component placement. At Intech, technicians are trained to handle complex assemblies with accuracy and efficiency.

5. Emphasize Design for Manufacturability (DFM)

DFM is the process of optimizing PCB designs for ease of manufacturing. Collaborating with Intech early in the design phase allows you to identify potential challenges, such as spacing issues or thermal concerns, and resolve them before production begins. This minimizes errors and ensures smooth assembly.

6. Ensure Material Quality and Traceability

The quality of materials used directly impacts the performance of your PCB. Intech sources components from trusted suppliers and ensures full traceability for each part, ensuring that only authentic and high-grade materials are used in custom electronic PCB assembly.

7. Monitor Production with Real-Time Data

Modern custom PCB assembly factories like Intech integrate real-time monitoring systems to track production metrics. These systems identify anomalies during manufacturing, enabling immediate corrections and reducing the risk of defective products.

8. Collaborate with a Reliable Partner Like Intech

At the core of successful custom PCB and assembly is a trusted manufacturing partner. Intech combines technical expertise, robust quality control, and customer-focused service to deliver outstanding results. From receiving accurate custom electronic PCB assembly quotes to final delivery, Intech ensures quality at every stage.

FAQ:

Q: How do I choose the right custom PCB assembly factory?

A: Look for factories with industry certifications, strong reviews, and proven experience in handling your type of PCB design.

Q: What is included in a custom electronic PCB assembly quote?

A: A detailed quote typically includes material costs, assembly labor, testing fees, and lead times. Intech provides transparent and competitive quotes.

Q: Can I monitor the production process remotely?

A: Many advanced factories, including Intech, offer real-time monitoring and regular updates during the production cycle.

Q: What testing is crucial for high-quality assembly?

A: AOI, functional testing, and environmental testing are essential to detect defects and ensure reliability.

With Intech’s expertise and commitment to excellence, you can confidently achieve superior quality in custom electronic PCB assembly while meeting your unique requirements.