What is the Difference Between PCB Manufacturing and PCB Assembly?

Date:2024-12-05 10:23:22

In the world of electronics, PCB board manufacturing and PCB assembly services are two crucial yet distinct processes that bring electronic designs to life. Whether you're an engineer, a hobbyist, or a business looking to partner with a reliable PCB assembly manufacturer, understanding these two processes can help you choose the right services for your needs. Let’s explore the differences between PCB manufacturing and PCB assembly in detail.

PCB Manufacturing: Building the Bare Board

PCB board manufacturing is the process of creating the physical circuit board. This step focuses on producing the blank PCB that serves as the foundation for electronic components. It involves multiple stages:

Design and Prototyping

The process starts with PCB design and assembly planning, where engineers create a blueprint using design software. The design specifies the board’s layout, layers, and copper traces.Material Selection

PCB boards are typically made from materials like FR4, a durable fiberglass-reinforced epoxy laminate. Other materials may be used for specialized applications, such as flexible PCBs.Etching and Layering

The copper layers are etched to create the pathways (traces) that connect various components. Multilayer PCBs undergo a lamination process to combine several layers.Drilling and Plating

Holes are drilled for vias, which allow electrical connections between layers, and the board is plated to improve conductivity.Silkscreen and Finishing

Labels and component markings are printed on the board, followed by the application of a protective solder mask to prevent oxidation.

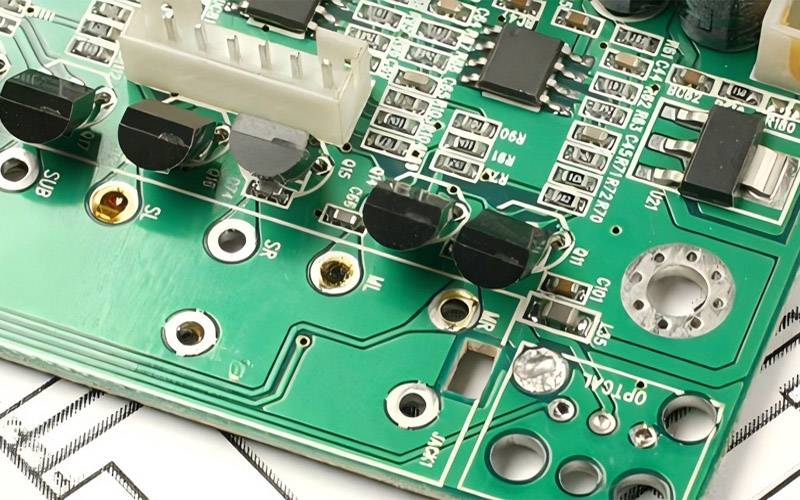

PCB Assembly: Bringing the Board to Life

PCB assembly services focus on placing and soldering electronic components onto the bare PCB. This process transforms the blank board into a functional device. The main steps include:

Solder Paste Application

A stencil is used to apply solder paste to areas of the board where components will be mounted.Component Placement

Surface Mount Technology (SMT) or Through-Hole Technology (THT) is used to place components such as resistors, capacitors, and ICs onto the board.Soldering

- Reflow Soldering: For SMT components, the board passes through a reflow oven where the solder paste melts and bonds components to the board.

- Wave Soldering: Used for THT components, the board is passed over a wave of molten solder to secure the components.

Inspection and Testing

After soldering, the assembled PCB undergoes Automated Optical Inspection (AOI), X-ray, and functional testing to ensure the connections work as intended.Packaging and Delivery

The final product is packaged and delivered to clients, ready for integration into devices.

Key Differences Between PCB Manufacturing and PCB Assembly

| Aspect | PCB Manufacturing | PCB Assembly |

|---|---|---|

| Focus | Creating the bare circuit board | Installing and soldering electronic components |

| Materials Used | Copper-clad laminates, FR4, solder masks | Electronic components, solder paste |

| Processes | Etching, drilling, plating, silk screening | Component placement, soldering, testing |

| Output | Bare PCB with no components | Fully functional PCB ready for use |

How They Work Together

PCB manufacturing and assembly are interconnected processes that form the backbone of the electronics industry. A PCB assembly manufacturer often collaborates closely with PCB board manufacturers to ensure a seamless transition from design to production. Some companies offer both PCB design and assembly, providing end-to-end solutions that streamline production and reduce costs.

Choosing the Right Services

When selecting a partner for PCB assembly services or PCB board manufacturing, consider the following factors:

Expertise and Capabilities

Look for a manufacturer with experience in handling your specific type of PCB, whether it’s rigid, flexible, or multilayer.Turnaround Time

Ensure they can meet your deadlines, especially for high-volume orders.Quality Standards

Check certifications such as ISO and IPC standards to guarantee high-quality production.Cost-Effectiveness

Partnering with a company that offers both PCB manufacturing and assembly can save time and reduce costs.

Conclusion:

While PCB board manufacturing focuses on creating the physical structure of the circuit board, PCB assembly services bring that structure to life by adding the necessary components. Together, these processes are essential for producing functional electronics. Partnering with a reliable PCB assembly manufacturer that provides both services can streamline your production, ensuring high-quality results.

Whether you need help with PCB design and assembly or high-volume production, understanding these differences will help you make informed decisions for your project.